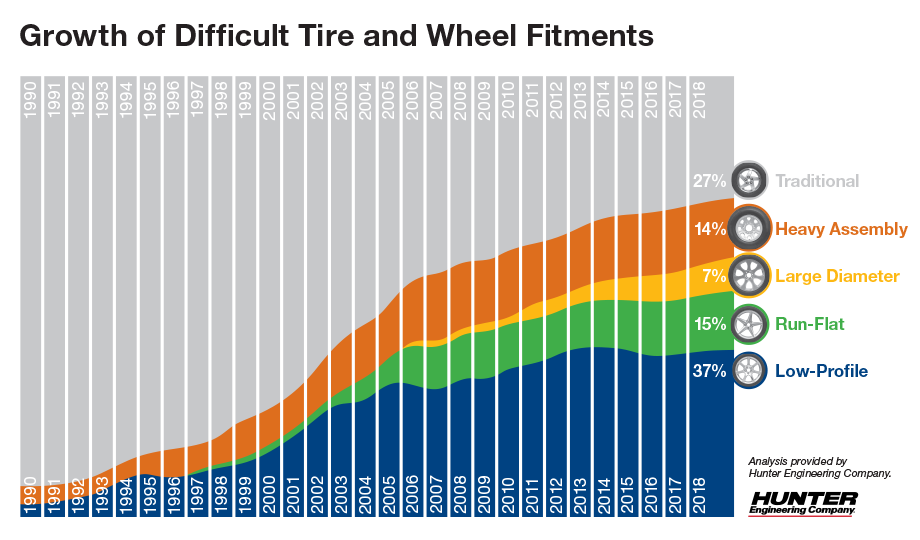

The Growth of Difficult Tire and Wheel Fitments

The trend continues — difficult-to-service tire & wheel assemblies now represent 73% of fitments offered by OE manufacturers.

Low-profile, run-flat, large diameter and heavy assemblies have proved difficult to service across multiple OEMs, requiring technicians to be skilled when using conventional tire changers. While low-profile tires have become the most prevalent in the last few years, all new fitment styles increase the likelihood of additional risks: damaging wheels, breaking TPMS sensors, or even technician injury.

It is vital for automotive service providers to be equipped with the most advanced, OEM-derived technology on the market today. This allows equipment, instead of the technician, to eliminate fitment challenges, as difficult-to-service assemblies continue to become the norm.

Heavy Assembly

- 30"+ overall diameter

- Benefits from wheel lifts and other weight control features

Large Diameter

- 20"+ overall diameter

- Somtimes require special clamping considerations

Run-Flat

- Very stiff

- Requires special procedures and press devices

Low-Profile

- 45-series or lower

- Often stiff

- Requires special procedures and press devices