Service rotors directly on the car for a quick, quality brake job.

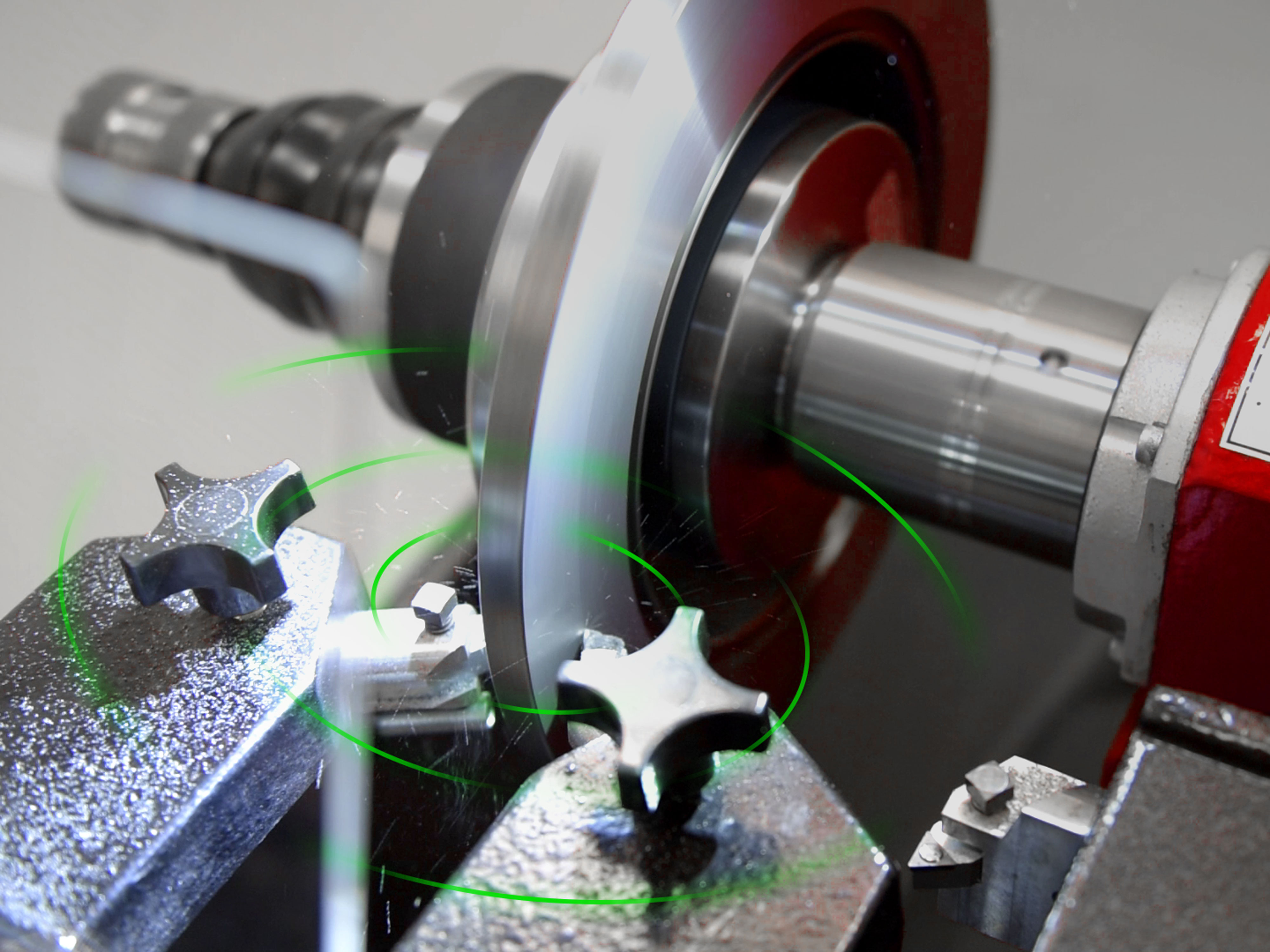

The BL Series Bench Lathe is a combination bench lathe that brings speed, precision and versatility to your brake service. The unique design of this combination lathe allows the operator to change the setup of the brake lathe from rotors to drums and vice versa with unprecedented speed and ease. Building on the same industry leading design of our previous bench lathe, the new BL Series Bench Lathe now has optional new features!

The BL Series Bench Lathe is a combination bench lathe that brings speed, precision and versatility to the brake shop. The unique design of this combination lathe allows the operator to change the setup of the brake lathe from rotors to drums and vice versa with unprecedented speed and ease.

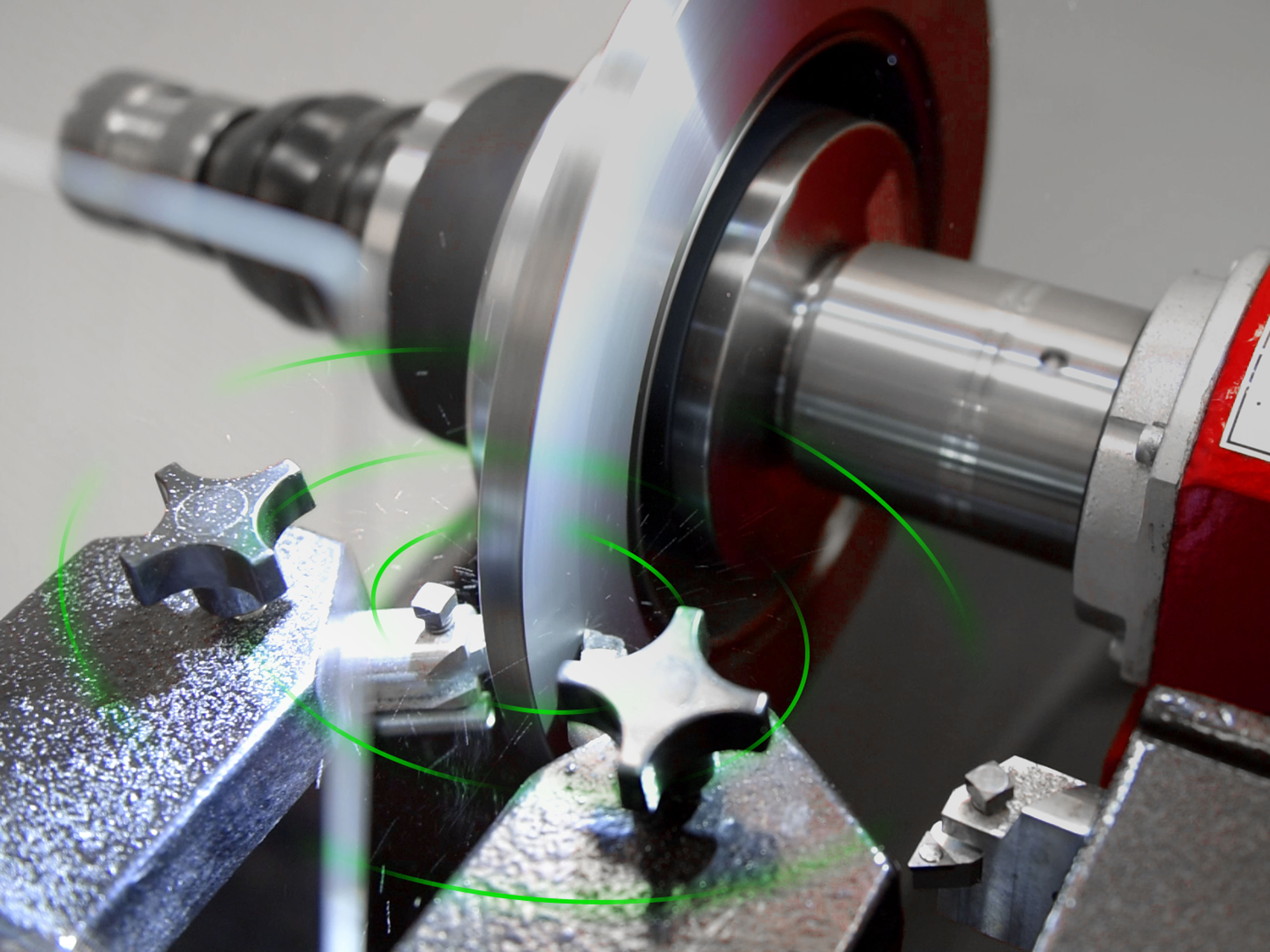

An in-depth explination on how Hunter Engineering’s Anti-Chatter Technology (ACT) works on Hunter's BL Series Bench Lathe and the on-car lathe, AutoComp Elite®. This technology provides better brake rotor surface finish while also allowing the lathe to cut much faster.

Hunter's Product Manager for Brake Lathes, Greg Meyer, takes you on a tour of Hunter's Bench Lathe and shows you important information regarding setup and calibration.

Greg Meyer, Hunter's Brake Lathe Product Manager, gives a thorough explanation on the various ways to install a brake rotor or drum, onto Hunter's Bench Lathe.

Hunter's Greg Meyer, Product Manager for Brake Lathes, demonstrates to how get the best surface finish when cutting a brake rotor, using Hunter's Bench Lathe.

In this final operation video, Greg Meyer explains how to cut a smooth finish on a brake drum, using Hunter's Bench Lathe.

Store frequently-used adaptors within easy reach.

Adjustable LED lights illuminate both side of workpiece

On-screen messages, animations, videos and Bit Minder increase efficiency.

Protect air quality with the ability to view the work piece during machining.

Variable spindle speed keeps chatter-inducing vibration from starting, making a smooth finish.

Instantly measure drum or rotor dimensions and depth of cut.

Prevent debris from falling to the floor.

Store operation manual, application charts and other reference materials.

Store tools and adaptors within reach but covered from brake dust.

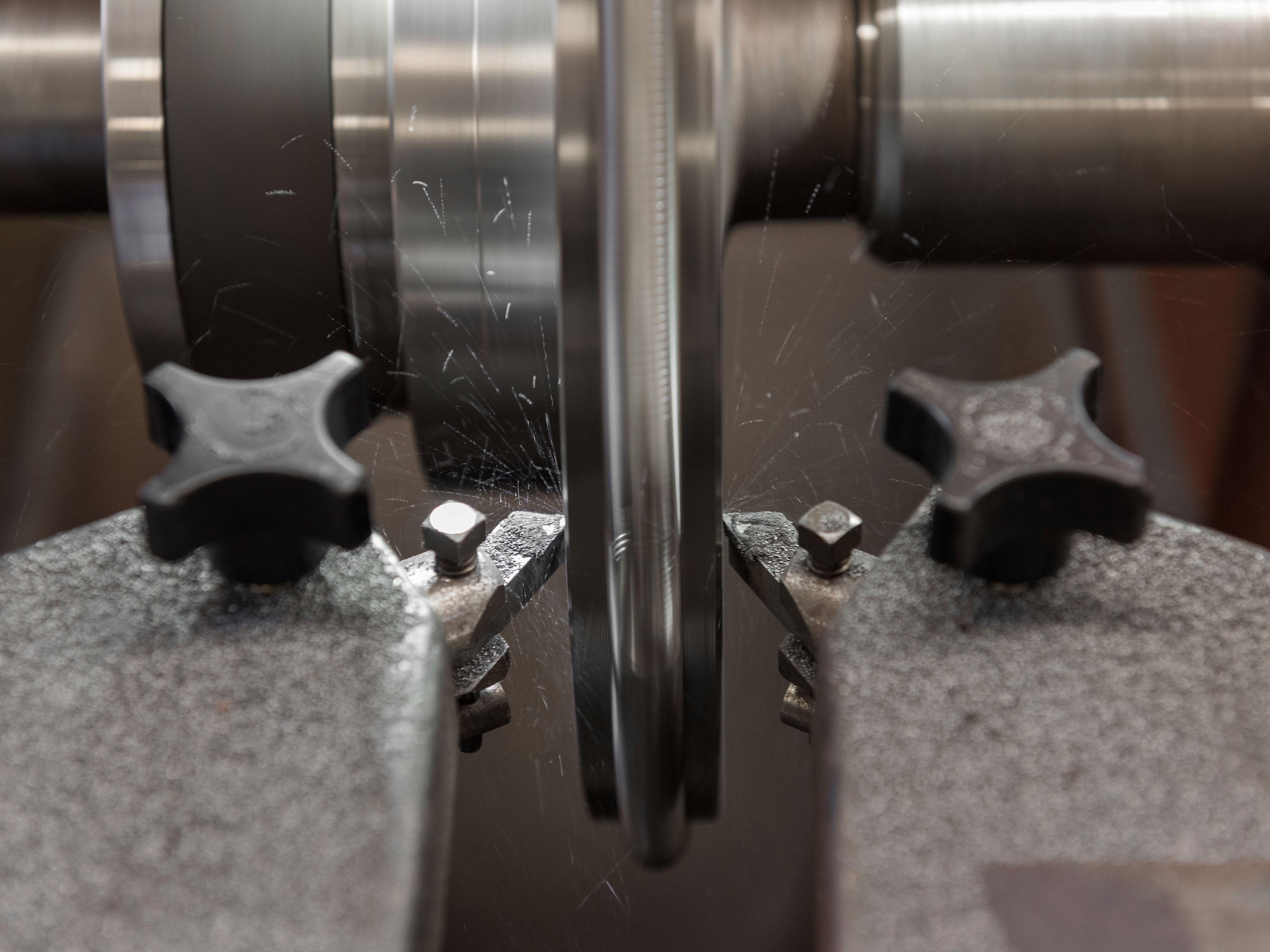

Dial in adjustable feed rate for faster, rapid removal to a slower, final surface finish. Allows technicians to cut rotors in one pass.

Optional Digi-Cal uses pushbutton speed control to instantly measure and display dimensions for quick calibration and greater accuracy

The calibration procedure for drums and rotors takes seconds, helping to prevent accidental removal of excess material

Optional DigiCal determines if the piece should be discarded prior to cutting.

Quickly change spindle speeds with the push of a button

Changing from rotors to drums takes seconds and is the fastest in the industry, greatly reducing setup time

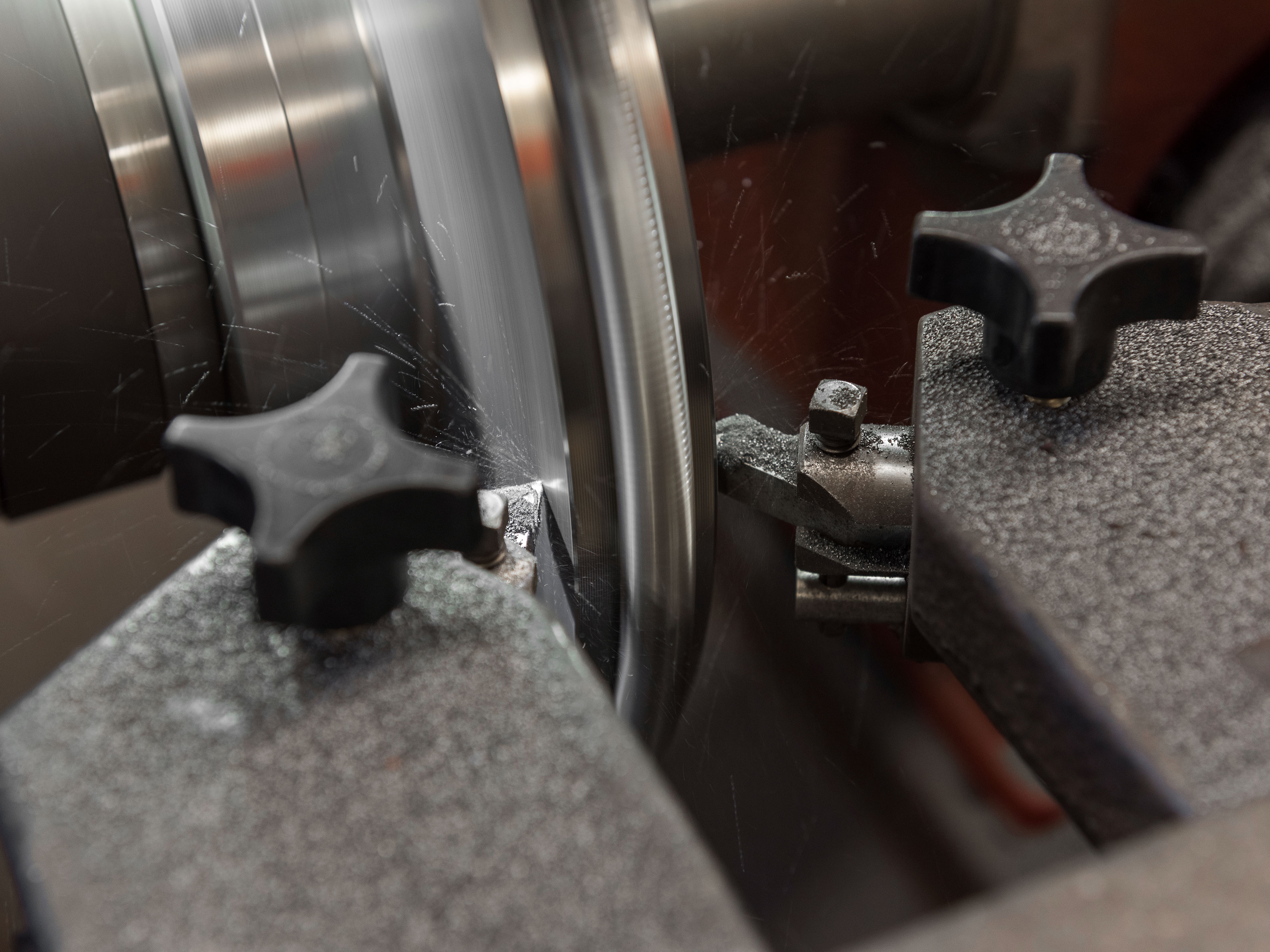

Faster-cutting and reduced-chatter positive rake standard (3 cutting tips). Durable, longer-life negative rake (optionl) tooling available (6 cutting tips)

Store frequently-used adaptors within easy reach with the optional heavy gauge, all-steel bench option with rear backboard

Speeds setup & prevents overtightening and mounting errors

Anti-Chatter Technology is optional on BL series brake lathes.

Provide a smooth, precise brake finish directly on the vehicle. Hunter's AutoComp Elite® on-car brake lathe is a cut above the rest.

Your local Hunter team will provide pricing information and can provide additional information on accessories, installation, training and more

|

|

|||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

To give you the best experience, this website uses cookies. By continuing to use this website, you are giving consent to cookies being used.

For information on cookies and how we use them, please visit our privacy statement and our terms of use.