Quick Check Drive® automatically captures license plate

Unmanned Inspection

Quick Check® Inspection

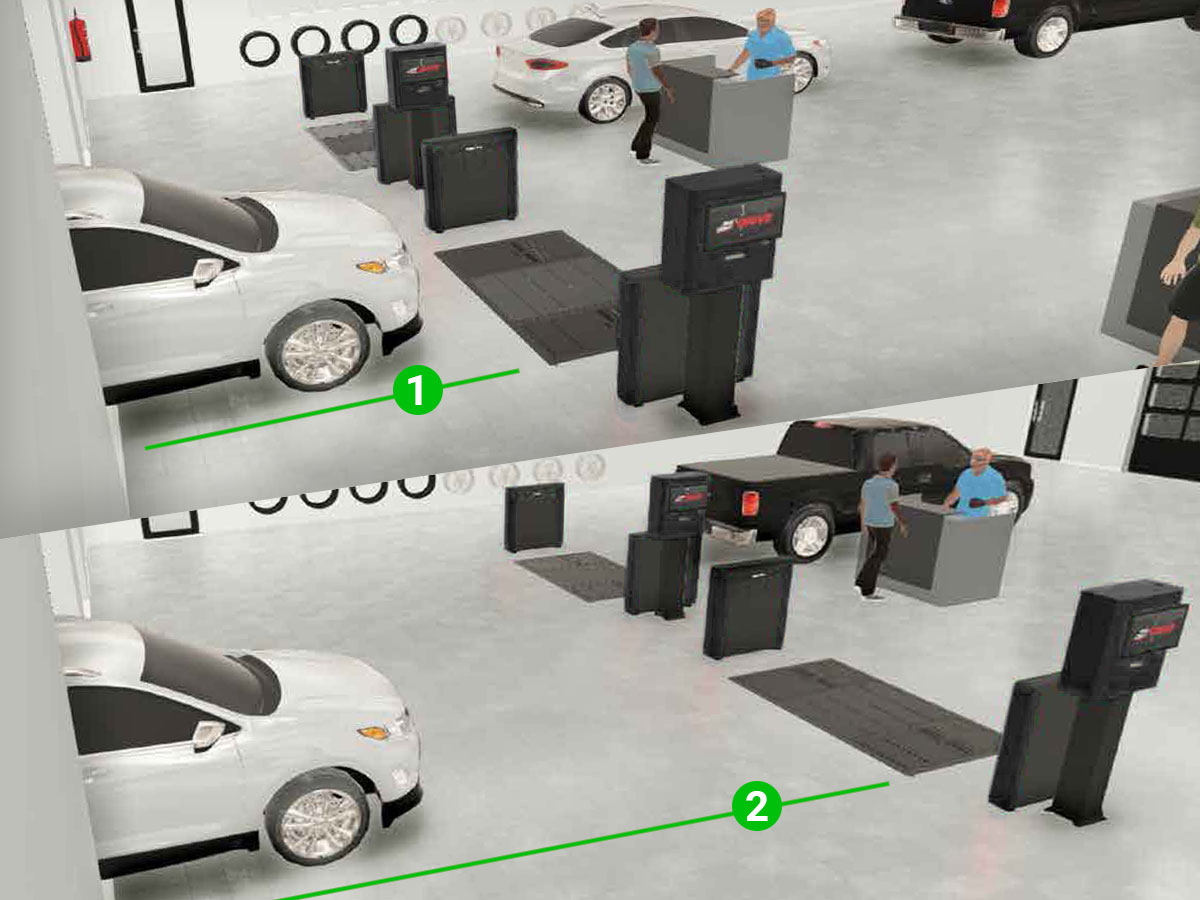

Accelerate your alignment and tyre business by checking the most important alignment angles and edge-to-edge tyre tread on every car that visits your shop, no stopping or labor required. Achieve payback on your investment within months!

Hunter Quick Check® Inspection

/

Quick Check® At-a-Glance

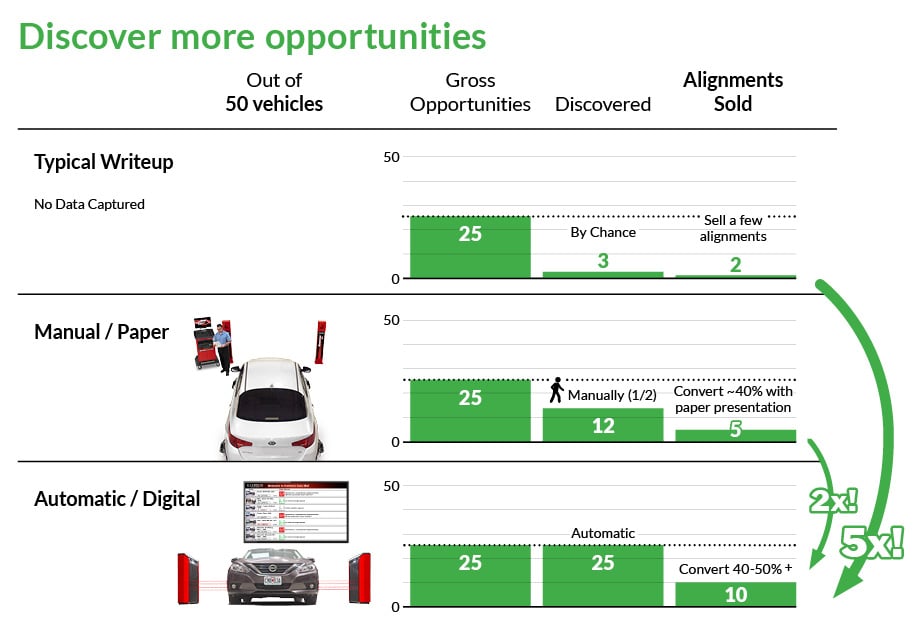

5x alignment opportunities

3D tyre results help sell critical replacements

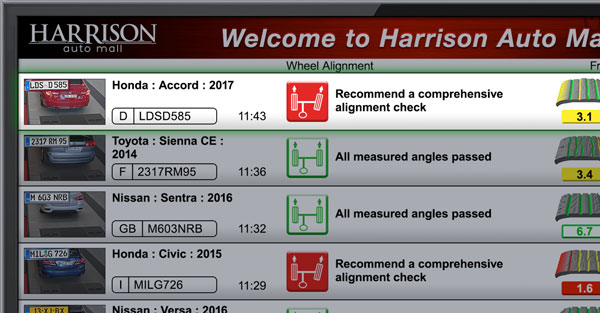

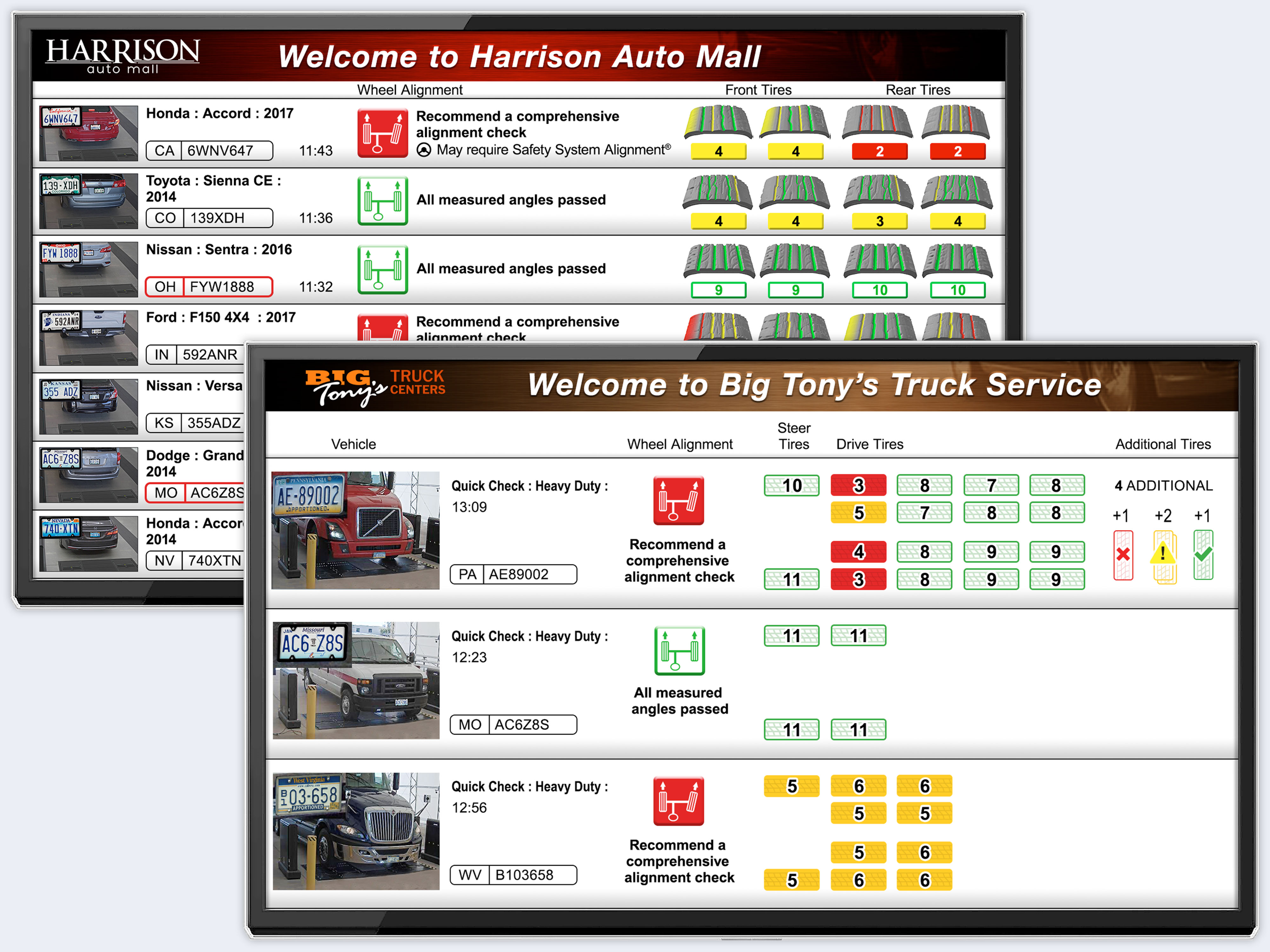

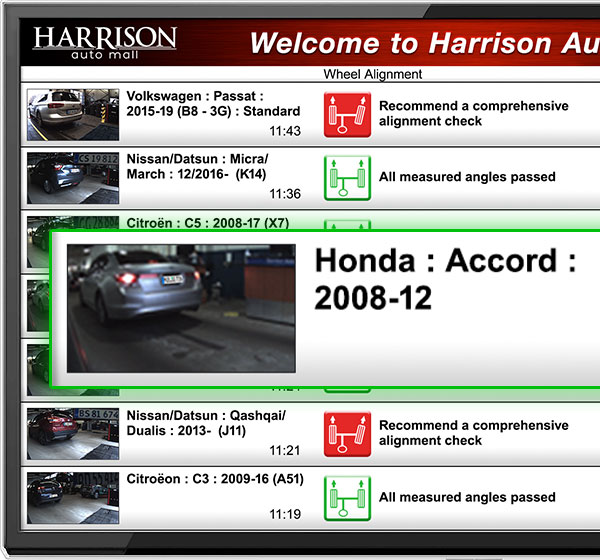

Flightboard™ results display provides complete transparency

Identify each vehicle automatically

Capture 40+ images of each vehicle as it enters

Streamline your intake process with touchless & efficient design

Extensive OEM support

Backed by Hunter's superior OEM specification database, pass/fail results are more accurate, saving time and avoiding comebacks

High-definition cameras

Automatically identify vehicles based on registered license plates. Add full-vehicle image capture of 40+ photos to prevent false damage claims (optional).

Accurate alignment results

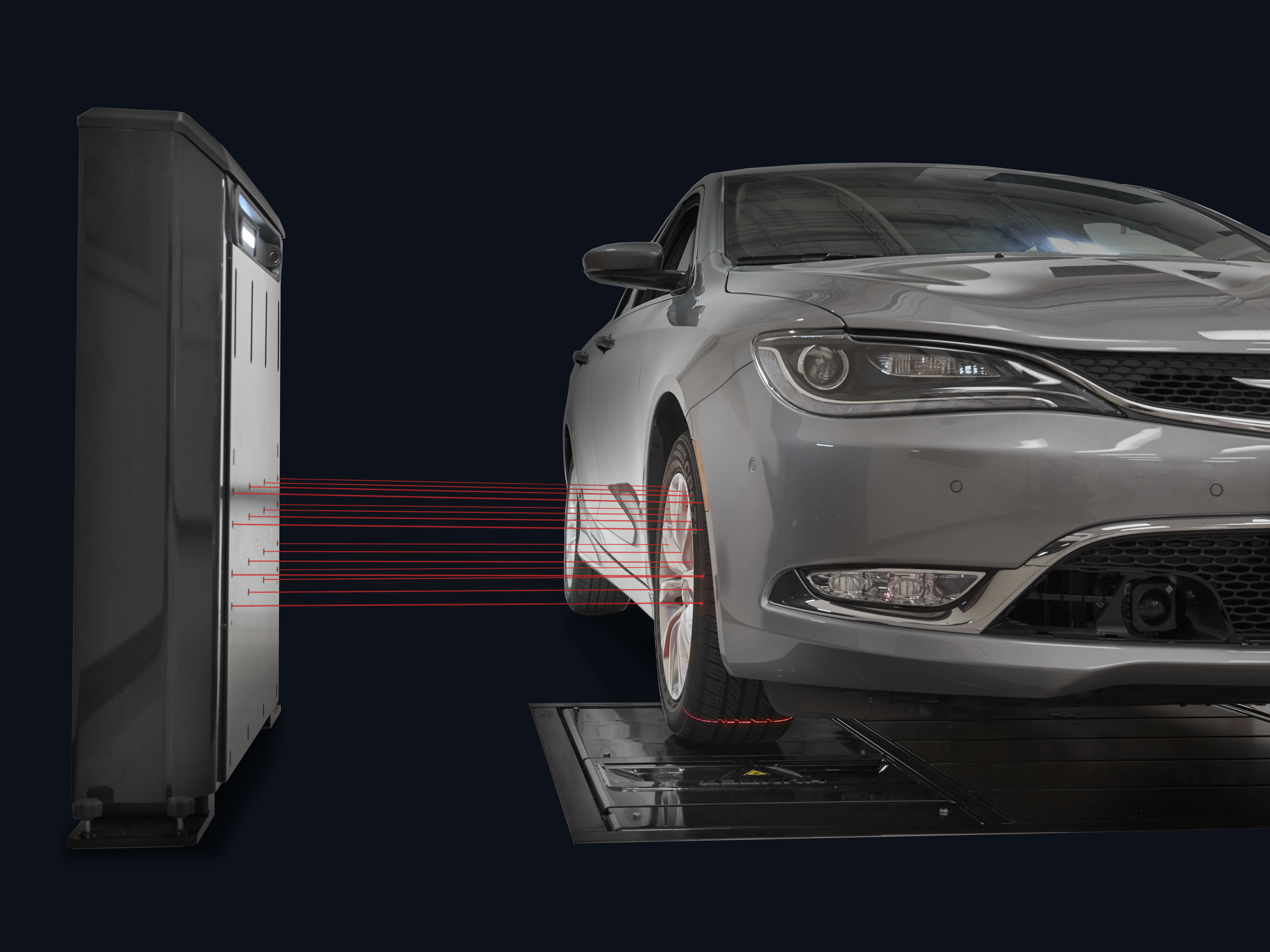

Optical and laser sensors accurately measure camber and total toe by taking 16 measurements per tire. Results are repeatable.

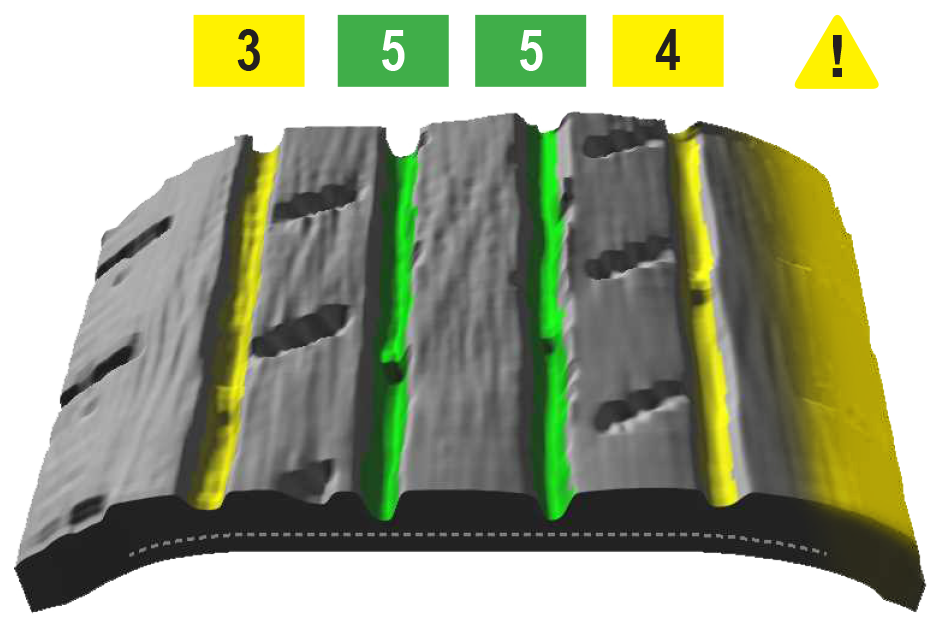

Automatic tyre tread measurement

Scan each tyre edge-to-edge and provide accurate 3D models to help sell replacement opportunities.

Ready when you are

Scan a vehicle every 3 to 5 seconds, only activating when a vehicle is present.

Eliminate trips around the car

Unmanned solutions mean faster scans with no labor

Capture data with unmatched technology

Eight cameras and 32 lasers produce results with world-class precision

Reduce your intake lane footprint

Requires 25-50% less bay space than other inspection units

Approved and recommended by multiple OEM partners

Quick Check Drive® at-a-glance

Hunter Engineering Company’s Quick Check Drive® system provides autonomous alignment audits powered by Hunter’s award-winning WinAlign® software.

"Quadruple" Alignment and Tyre Sales

Real users are reporting quadrupled alignment and tyre sales.

Santa Maria Dealerships turn inspection 180 degrees with Hunter unmanned inspection

Unmanned drive-through alignment and tread inspection in 15 seconds.

Morgan Auto Group quadruples tire and alignment sales

Joe Schlueter, Morgan Auto Group's VP of Fixed Operations, talks about the technological advantages and increased sales generated by Quick Check Drive® and Quick Tread Edge®.

Plaza Tire Service “adds gross profit and revenue”

Mark Rhodes, President of Plaza Tire Service®, has invested in Quick Check Drive® and Quick Tread Edge® systems at all of the new Plaza Tire locations being built and has the goal of putting the inspection system in each of Plaza’s 67 locations.

Pouring concrete was a no-brainer for Suntrup

Service Director of Suntrup Automotive Group, Elliot Silk, explains why Quick Check Drive® was the best investment made to help sales, retention and overall customer experience at Suntrup Kia South.

Quick Check Drive® technical overview

The completely unmanned system uses patented measurement technology to scan a vehicle as it drives through without stopping and provides total toe and individual camber measurements in seconds.

Hunter's Quick Check Drive® at Eddy's Toyota

Eddy's Toyota in Wichita, Kansas installed Quick Check Drive® automated alignment inspection systems in their service drives and saw an immediate return on investment, increasing their alignment sales by 300%!

Quick Check Drive® paid off in months at Jay Wolfe Toyota

Jay Wolfe Toyota of West County installed two Quick Check Drive® automated alignment inspection systems in their service drive and saw an immediate return on investment, by doubling their alignment business.

Quick Check Drive® at Cable-Dahmer Chevrolet

Cable-Dahmer Chevrolet of Independence, MO has equipped their service drive with Hunter's Quick Check Drive® automated alignment inspection system.

Alignment business doubled with Push Reports at Greenway

Greenway CDJR was looking for more insight into how their Hunter Engineering equipment was being utilized in their service drive to help drive their fixed operations business.

CALCULATE YOUR RETURN ON INVESTMENT

View your rapid return on investment with automatic alignment inspection

Your Return On Investment

Input your vehicles/day and profits to calculate your payback

| Additional Daily Profit |

|

|---|---|

| Annual Return |

|

| Equipment Investment |

$

|

| Equipment Payback |

months!

|

Notes

- One alignment system per 50 cars inspected is typically required to support additional alignment opportunities

- See current tax code. In many cases full purchase price of equipment is tax deductible

- Concrete and site construction work are not included in the price of the equipment.

- Payback calculation: (Equipment Investment) / (Cars/day X Failure rate X acceptance rate X typical profit X 5.5 day/week X 4 wks/mo)

Contact for pricing or demo

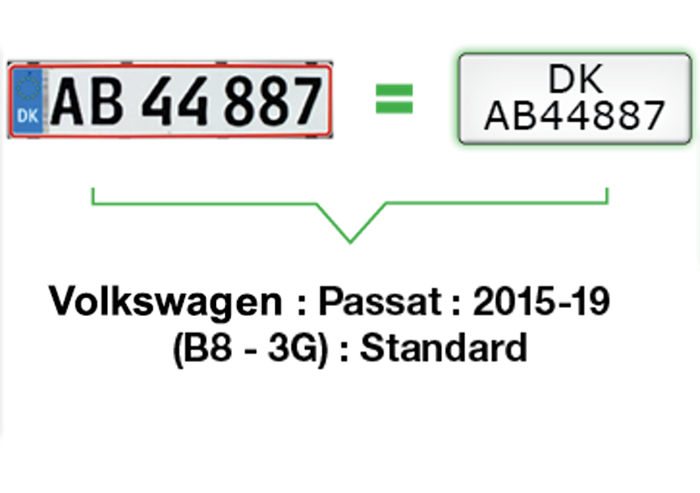

License plate to KType for unmatched spec resolution

1. Capture license plate

2. Specification lookup

QuickPlate™ uses license plate to automatically resolve specs

3. Generate Pass/Fail Results

Quick Check Drive® generates autonomous pass/fail results!

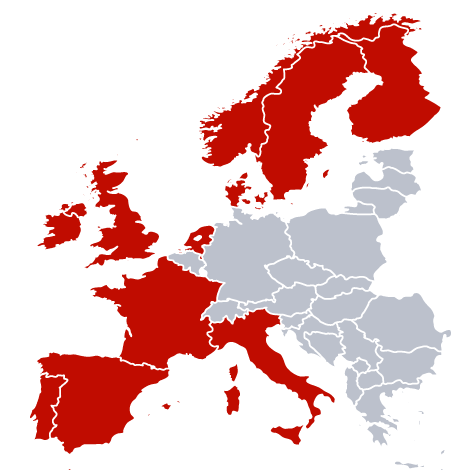

QuickPlate™ is supported in the following countries

Autonomous results - no license plate required

1. Body Damage Cameras

Quick Check Drive® captures vehicle images with Body Damage Cameras

2. Determine Specs

WinAlign® analyzes vehicles for make, model, and generation to determine specs

3. Generate Pass/Fail Results

Quick Check Drive® generates autonomous pass/fail results!

Quick Auto ID currently supports the following OEs in Europe

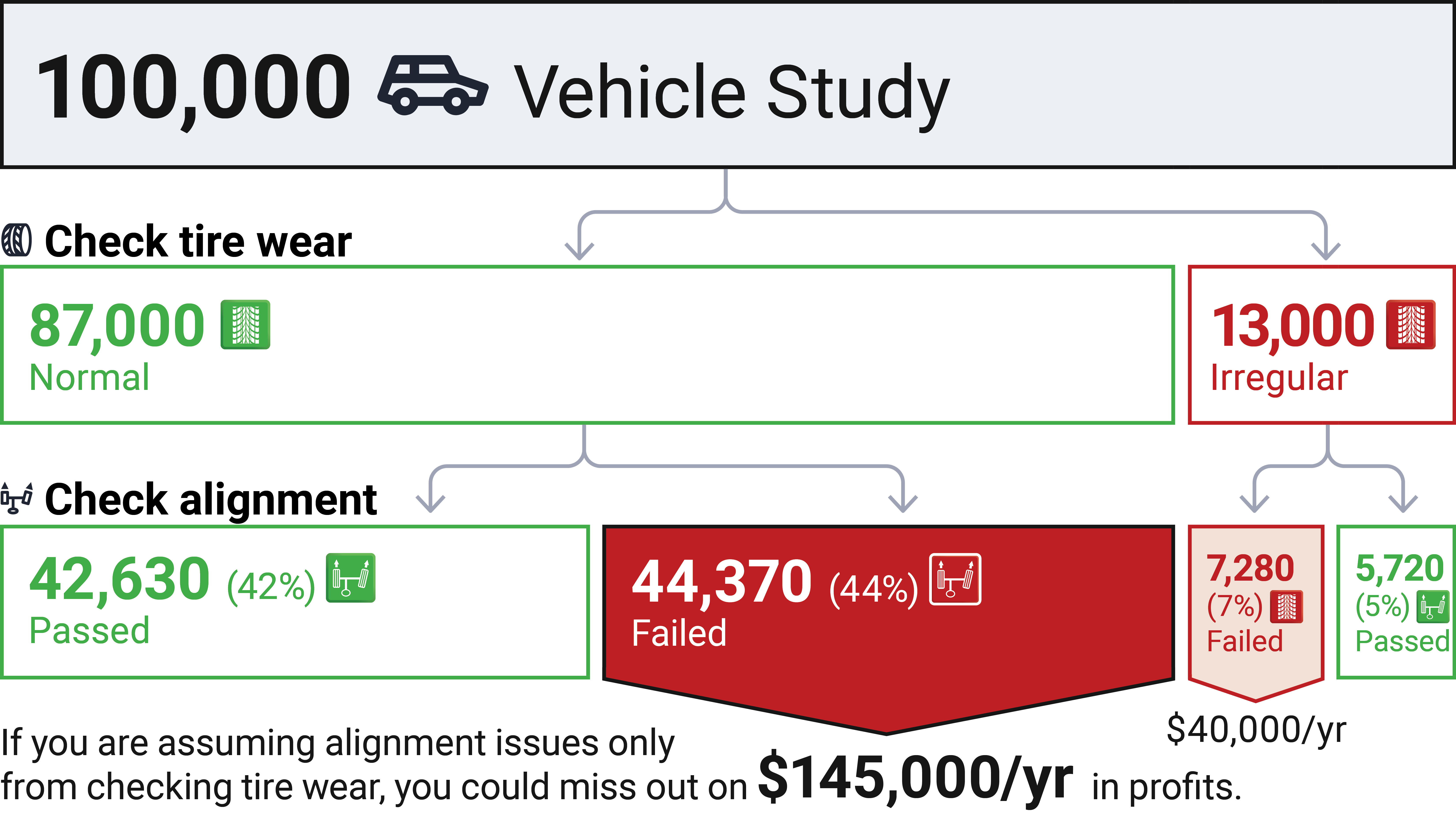

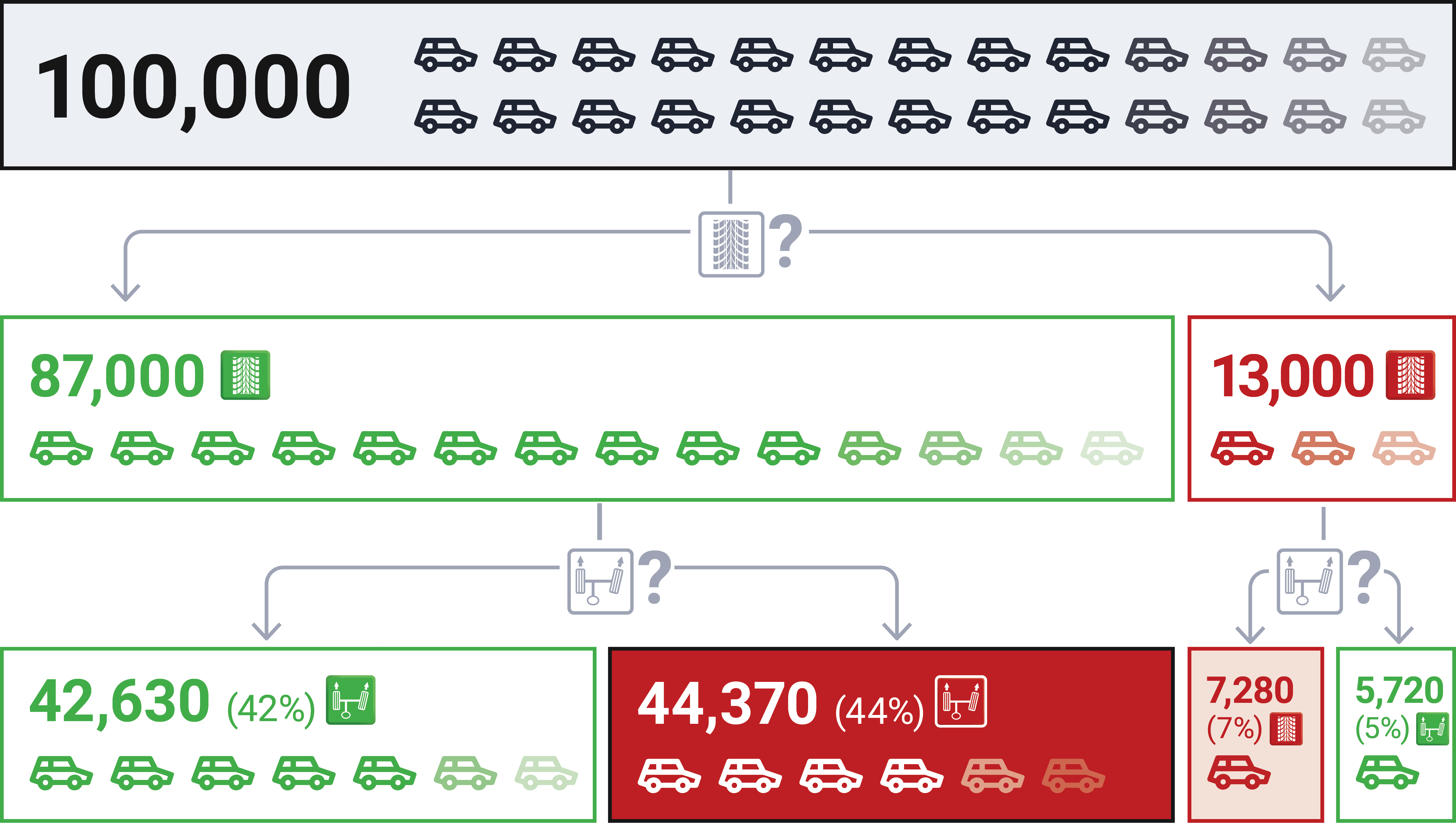

Don't lose out on hidden alignment opportunities

In a 100,000 vehicle study, irregular tyre wear is present only 13% of the time. If you check only tyre wear and base your alignment assumptions on that, you are missing a wealth of opportunities from vehicles that are out-of-alignment but show regular tyre wear.

Quick Check Drive® checks every vehicle's alignment.

Identify every vehicle through built-in, automatic cameras

Provide complete customer transparency with Flightboard™ results display

Hunter's Flightboard™ digital display results offer complete transparency for your customers.

RESULTS VISIBLE TO ALL

Customer vehicle results display automatically in waiting area or service drive

GO BEYOND PAPER RESULTS

Digital presentation helps inform customer before reviewing with technician or service writer

Choose the right inspection equipment for your shop

Light-Duty

Class I Vehicles

-

- QCD alignment sensors

- QTEF tread depth

- WU592 WinAlign® console

Suitable for wheel assemblies up to 32 in. and up to 7,000-lb. axle weight.

-

- Compact

- Sedan

- SUV

- Pickup

- Transit Van

Medium-Duty

Up to Class V Vehicles

- QCD alignment sensors

- QTHD tread depth

- WU592MD WinAlign® console

Suitable for wheel assemblies up to 32 in. and from 7,000-20,000 lb. axle weight.

- RV

- Dual-Axle Pickup

- Delivery Van

Heavy-Duty

Class VI Vehicles and Above

- CHD alignment sensors

- QTHD tread depth

- WU592HD WinAlign® console

Suitable for wheel assemblies greater than 30 in. and from 7,000-20,000 lb. axle weight.

-

- Box Trucks

- Dump Trucks

- Heavy Utility Vehicles

- Municipal and Commercial Buses

- Over-the-Road Tractor Trailers

Prevent false damage claims by capturing 40+ images of every vehicle

Safeguard your operations

Save your store thousands of dollars in false vehicle-damage reports

Quickly review images with HunterNet®

Cameras capture an average of 40 images per vehicle, and the intuitive interface displays vehicle info and date of service

Generate collision repair business

Utilize your own collision repair service or refer customers to an affiliate repair shop.

Intuitive Damage-Cam interface displays vehicle information and date of service. 90-day image storage standard. Yearly subscription charges apply.

Selling power in your hands

- Data driven selling is trusted and powerful

- Results are personalized to the customer

- Customize the layout that sells the highest impact

Inform your customers on critical tyre replacement services

Measuring tyre tread edge wear is critical to proactive tyre safety

A bald tyre edge will affect wet weather traction, resulting in longer stopping distances and poor handling. If the edge portion of the contact patch has no tread, it cannot shed water.

Recommended add-ons

Solve difficult install situations such as low lighting, daylight glare, and field of view obstacles. Cameras can be installed indoors, ceiling or wall-mounted, center or off-center.

Did you know?

Alignment issues are the leading cause of tyre wear

Toe and camber misalignment can cause irregular tyre wear...

Are you ready for every profitable service opportunity that enters your shop?

UNMANNED COMMERCIAL INSPECTION

Instant, unmanned inspection for heavy-duty delaers, repair shops and fleets

الربط بين معدّاتك وشركتك

- تعزيز أداء متجرك إلى أقصى حدّ

- تبسيط النقاشات مع العملاء باستخدام أدوات البيع

- عرض المزيد من المعلومات عن الهيكل السفلي للسيارة

Recall past inspections

View previously inspected vehicles, recall printouts, and view body damage camera photos.

Track revenue

Track your profits and potential amount if all needed services were sold.

View your performance

Set goals and see how your business performs day-to-day.

Receive daily reports

Setup to receive daily Push Reports to keep your goals and performance in check.

GALLERY

Documents

-

Brochures

-

Ordering Guides

-

Specification Sheets