- 368–622 mm rim diameter

- 100 mm min rim hole diameter

- 1473 mm max tire diameter

- 686 mm max width

- 700 kg max weight

- 9 rpm CW & CCW

- 208-240V, 1ph, 60Hz, 20A

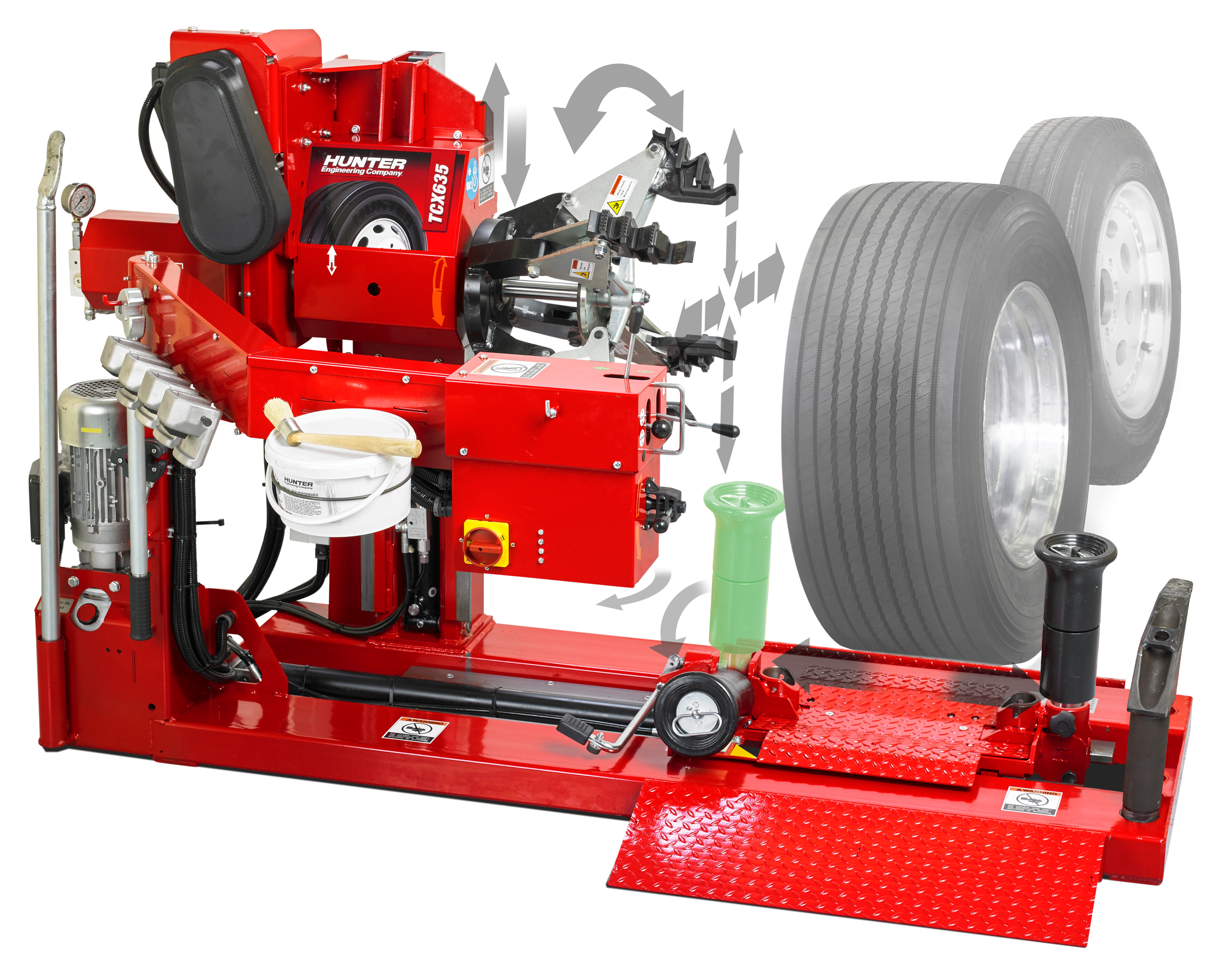

Safe and fast tyre changers for big tyres

Hunter Heavy-Duty Tire Changers

/

Heavy-Duty Tyre Changers

Safe and fast tyre changers for big tyres

Whether your need is a fast and safe tyre changer for semi-truck tires, or a tyre machine that will change skidder tyres, Hunter has a model to suit. Hunter's heavy-duty tyre changers support over-the-road truck tyres with none of the fatigue and safety risk of bars and hammers. The TCX645HD heavy-duty tyre changer can do all that, plus handle implement tires up to 228,6 cm (90”) in diameter.

Features at-a-glance

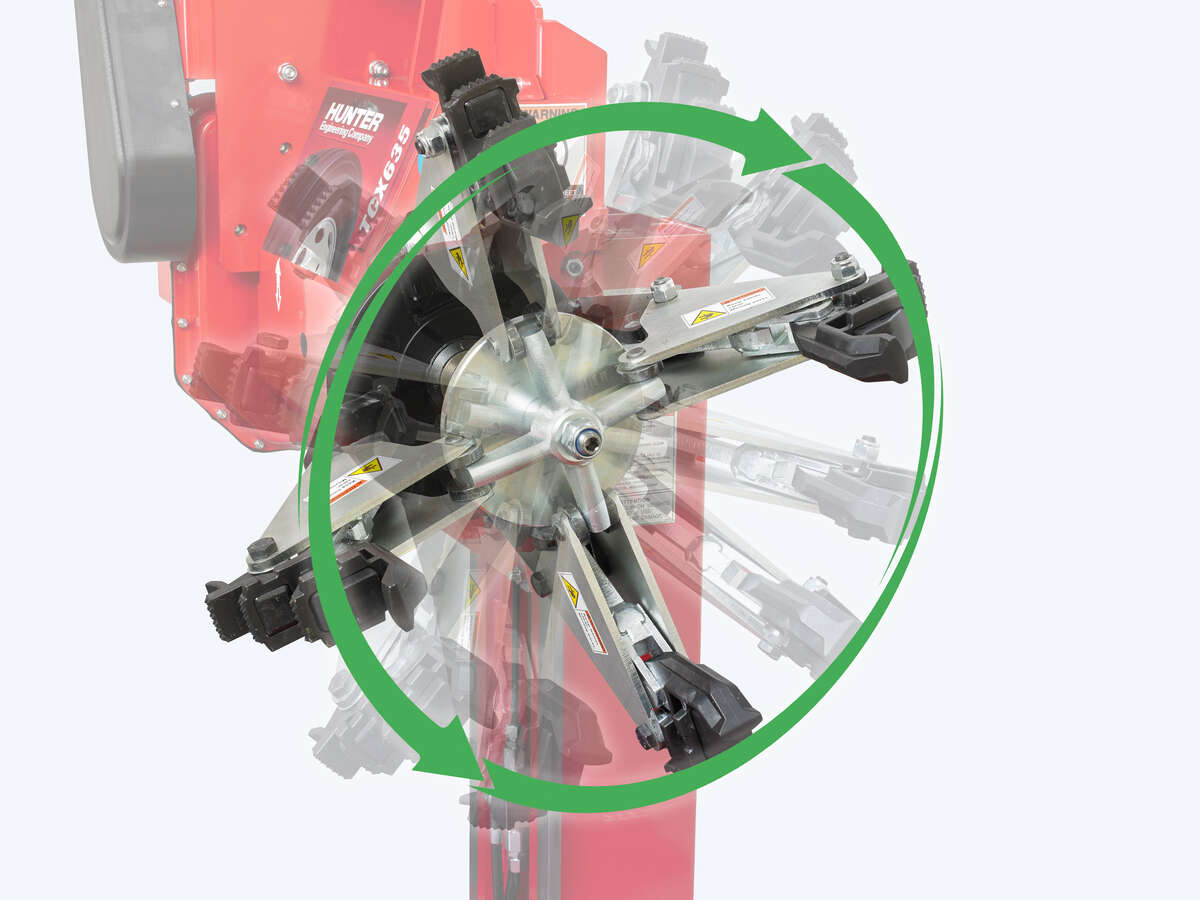

- Tulip-style wheel clamp

- Safe controls

- Roller Demounting

- Standard Hook

Thomas Tire relies on Hunter to maintain trust with HD and commercial customers

Customers have long relied on Thomas Tire in Asheville, NC to take care of their HD vehicles, says co-owner Sally Thomas. In turn, Thomas relies on Hunter equipment to maintain that trust. “Our dad was always a firm believer in investing in quality, and that’s what we’ve done,” she says.

TCX635 Heavy Duty Tire Changer

Plenty of power and speed to change even the most difficult HD truck tires easily and safely.

The Hunter TCX635HD Tire Changer

See the easy-to-use features of the Hunter TCX635HD tire changer that help technicians properly service heavy-duty wheel assemblies.

TCX645HD Heavy Duty Tire Changer from Hunter Engineering

TCX645HD Quick Ops-Road Wheels

Watch the process of demounting and mounting road wheels on the Hunter TCX645HD heavy-duty tire changer.

TCX645HD Quick Ops-Skidder Wheels

See how easy it is to properly and safely service skidder wheels on the Hunter TCX645HD heavy-duty tire changer.

PRODUCT FAMILY AT-A-GLANCE

TCX635HD

Extra torque, extra speed

TCX645HD

Truck tires to skidders

- 356–1168 mm rim diameter

- 100 mm min rim hole diameter

- 2299 mm max Diameter

- 1067 mm max width

- 997,9 kg max weight

- 10 & 5 rpm CW, CCW

- 230V, 3ph, 60Hz, 26A

TCX660HD

2-speed clamp rotation motor

- 356–1422 mm rim diameter

- 100 mm min rim hole diameter

- 2600 mm max diameter

- 1498 mm max width

- 2500 kg max weight

- 5.25-10.5 rpm

TCX635HD FEATURES

Operator-friendly design

- Low risk - No hammers, no bars, no lifting very heavy tires

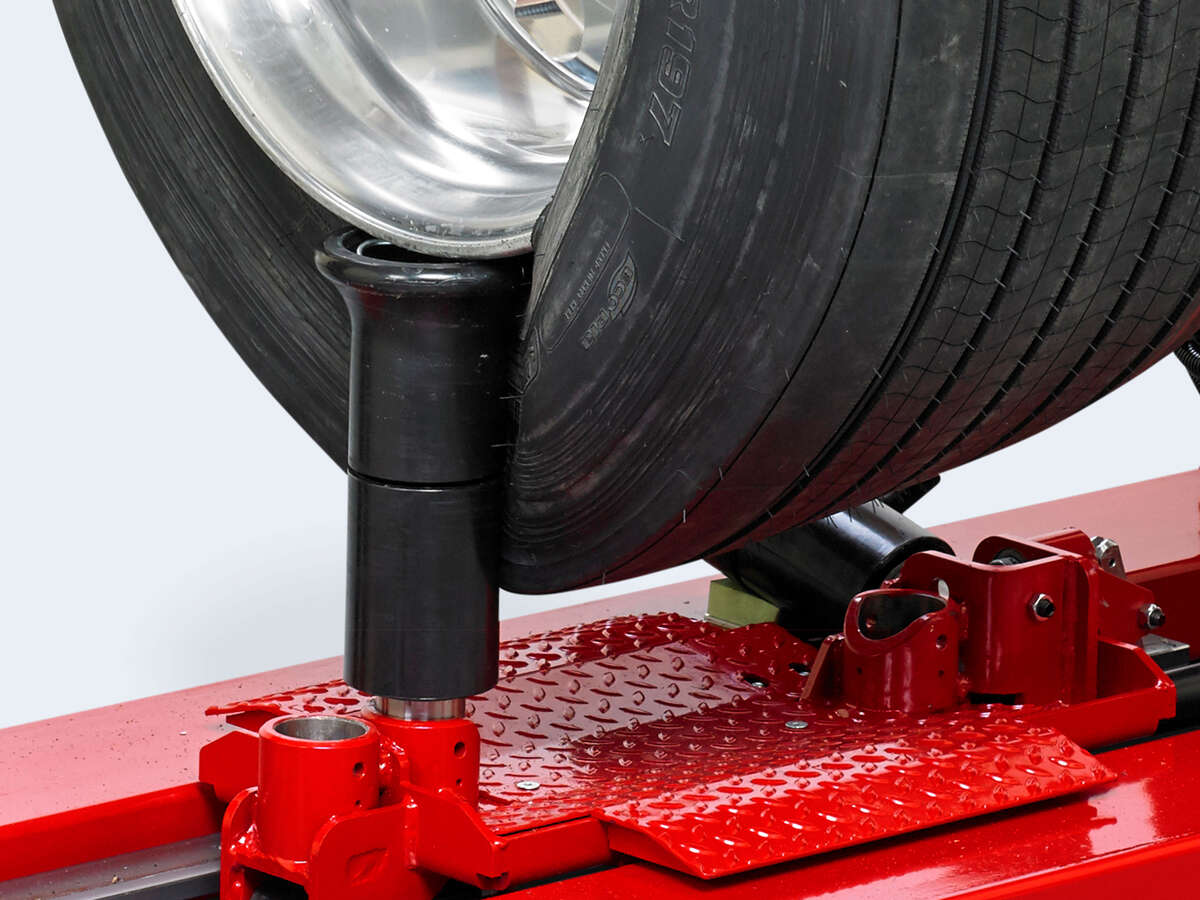

- Low service height - Easy to roll on and no fear of tire falling off during demounting

- Optional ramps - Popular "plus" model includes ramps, carriage cover, and mounting bar

Superior wheel accomodation

- Easy match mounting - Rotate tire on rim when needed for the smoothest ride

- Specialty rim friendly - Standard hook can be used to mount and demount challenging tires and rims without fear of damage

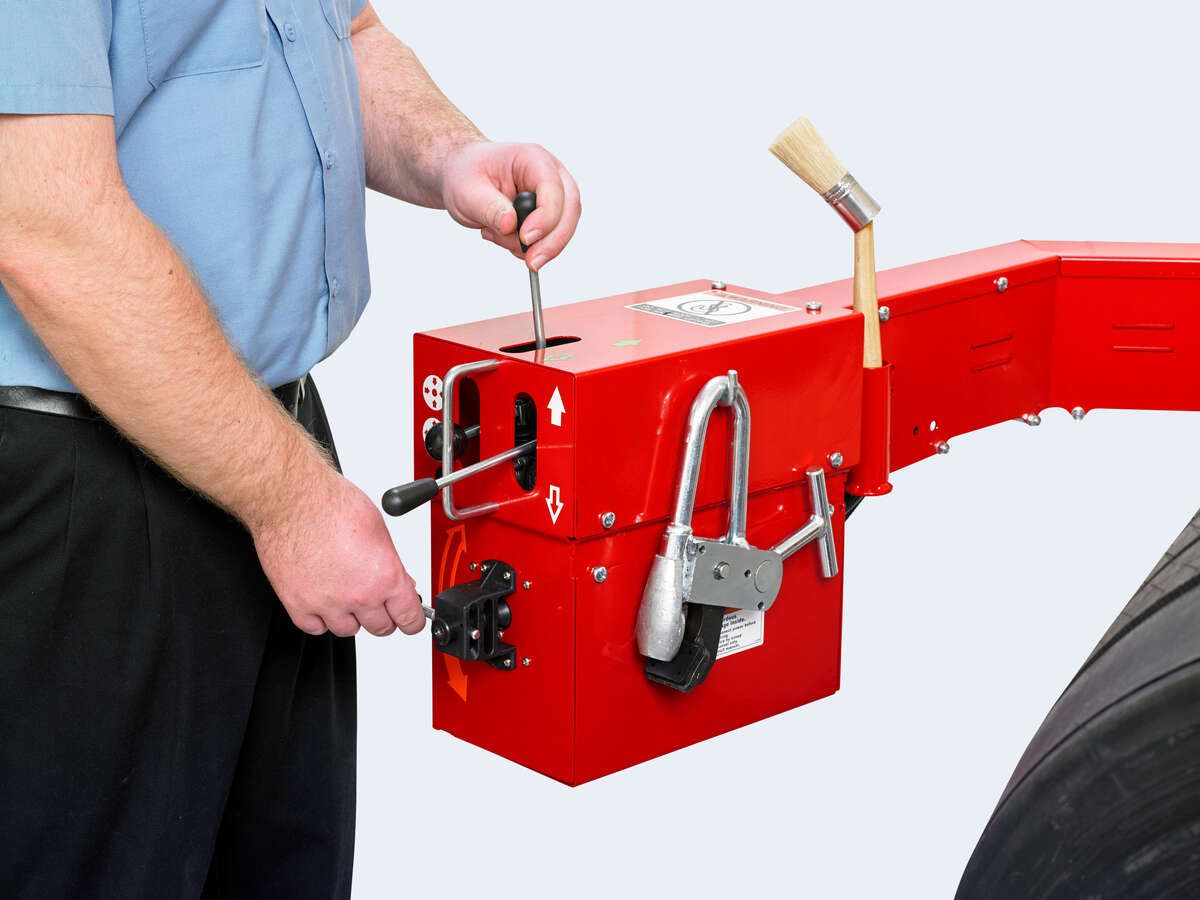

- Simple controls - Easy to use levers control all operations in a convenient and safe operator position

- Versatile jaws - Secure small center holes, thick wide based allow wheels, centerless wheels, and much more

Powerful tools to assist

- Fast and easy rollers - Most tires can be pushed on and off, no switching tools

- Inner "drop roller" - Speeds service times, never a need to remove to make room

- Hydraulic carriage - Maximum power and fast tool positioning

TCX645HD FEATURES

Operator-friendly design

- Mobile controller - Full access to controls when servicing the front or back of large assemblies. (Wireless optional)

- Low risk - Use powerful tools instead of bars and hammers. No lifting of very heavy assemblies

Superior wheel accomodation

- Versatile jaws - Clamp center holes as small as 100 mm (3,94”), or rims as large as 1168 mm (46”)

- Optional skidder clamp - Useful when servicing difficult skidder style double drop center wheels

- Spring loaded hook / disc roller - Mount and demount the toughest tyres with minimal risk of rim damage

Convenient functions

- Two speeds - Select high speed for bead loosening or easy assemblies. Use low speed for the tough ones

- Speed carriage - Quickly shuttle the carriage from front to rear of the rim

- On-board storage - Keep standard and optional accessories organized

Match-mounting is easy!

When combined with Hunter's heavy-duty wheel balancers, the heavy-duty tire machines provide match-mounting capability for achieving the smoothest possible ride.

Specifications

Specifications

|

|

|||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gallery

Because of continuing technological advances, features and configurations shown in customer photos may vary.

Documents

-

Brochures

-

Specification Sheets

-

Accessories

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.