Hunter helps Italy’s Sedall Pneumatici handle variety of tire customers and services

Sedall Pneumatici in Italy’s Brescia province has expanded into a wide variety of tire services and customers over the years. Local distributor LMV and Hunter Engineering have helped by providing a wide variety of tire service equipment.

Italy’s Pneustirolo sees instant results with Hunter equipment

Pneustirolo uses Hunter balancers, tire changers and aligners, and just recently added the Revolution™. “We’ve just had it a few weeks, but we can already see we’re saving time,” Andre says. “One mechanic can now do the work of two.” Professional service also counts with Andre.

Mexico’s Tersa Car Service uses Hunter equipment to make customers “fall in love”

For branch manager Aldo Cazeres at Tersa Car Service in San Pedro Garza Garcia, Mexico, the value of Hunter equipment is everywhere he looks. “We have the proof that we can do things fast, easy and profitably,”

Hunter equipment provides “amazing results” for Aston Martin Brussels

Placing high importance on efficiency and reliability, Aston Martin found what it was looking for in Hunter Engineering equipment. There wasn’t much drama when manager Freddy Loix was considering which tire and wheel service equipment would best bit Aston Martin Brussels.

Hunter alignment technology delivers accuracy and confidence for Nicaragua’s Grupo Q Workshops

Alfonso Cardenas is responsible for alignment and balancing at Nicaragua’s Grupo Q Workshops, and he’s glad he is. “Thanks to the acquisition of the new Hunter aligner, our company has improved its service and meeting our customers’ demands,”

Hunter equipment allows Australia’s Bump Shop to handle modern vehicles

Chris Patel describes Australia’s Bump Shop as a panel shop that specializes in collision damage. Upgrading to a Hawkeye Elite® alignment system paid dividends in multiple way, he says. “The Hawkeye Elite® has improved our efficiency, because it’s a lot easier to use and we can do a lot more of the modern cars we get nowadays.”

“Hunter kept coming up number one” for Australia’s Nudgee Automotive

When Nudgee owner Gary Homan was looking for an efficient and reliable alignment system, the choice was quickly made for him. “I kept looking around, and Hunter kept coming up number one,” he says.

Kuwait’s Speedmate believes Hunter equipment defines quality service

Speedmate Service Center is known for providing high-quality, bumper-to-bumper service for its customers, says service manager Sunil Kannadipurath.

Pals Tyres triples down on Hunter wheel and tire equipment

Service and tires center Pals Tyres found Hunter Engineering and its distributor Madhus Garage Equipment to be the partners they were looking for.

Chennai's V.S. Enterprises

Tire dealer V.S. Enterprises prides itself on providing its customers with a complete service experience. Hunter equipment helps get them in and out as quickly as possible.

Najera Alineado treats the problem, not the symptom, with Hunter alignment equipment

As a shop specializing in alignments, Ivan Najera of Costa Rica’s Najera Alineado & Tramado knows he needs specialized equipment. “We need something that identifies certain problems, factors and conditions by measuring the entire geometry of the vehicle,” he says. “We need to make an efficient diagnosis.”

NEXTGEN Autoshop seeks, and finds, best-in-class service and equipment

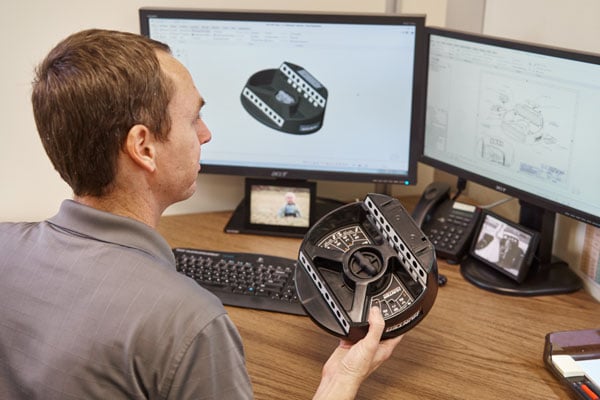

Giridharan, President of NEXTGEN Autoshop in Coimbatore, India was looking for a way better serve its high-performance car client base. Seeking to be the best, they went after the best equipment and found it in Hunter’s HawkEye Elite® alignment system and the Road Force® Elite wheel balancer, distributed by Madhus Garage Equipment.

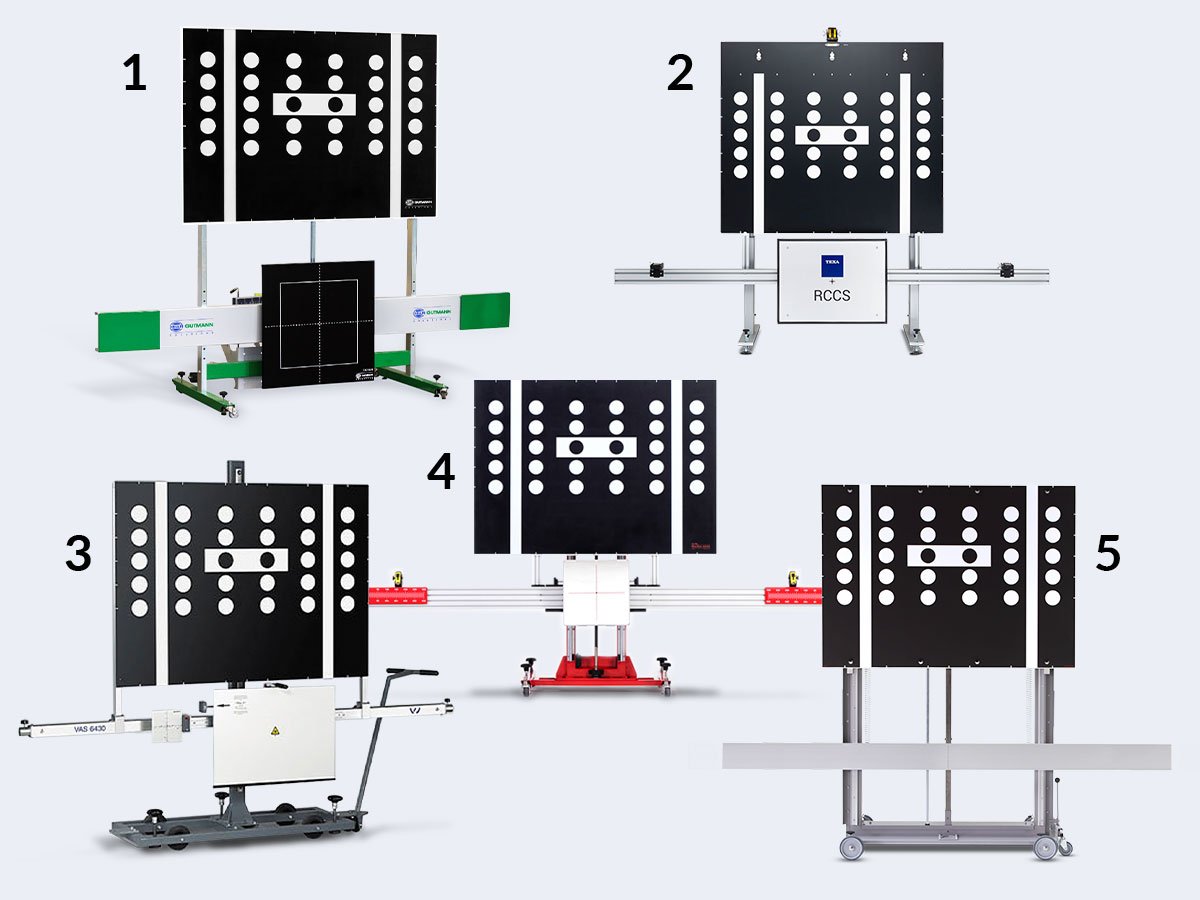

Define the standard with Hawkeye Elite® + WinAlign®

With 70,000 systems in use worldwide and a database supporting more than 285 million vehicles, HawkEye Elite® and WinAlign® have long defined the performance standard for alignment equipment past, present and future.

70-Second Alignment Check

Fast setup and quick results in 70 seconds makes HawkEye Elite® the most efficient and product wheel alignment system.

Why Do Cars Need Wheel Alignment?

When your car is out of alignment, you may experience irregular tire wear, handling problems or a crooked steering wheel. A wheel alignment adjustment can correct these problems.

Fully Integrated Alignment

Hunter's fully integrated alignment system reduces the technician's trips around the vehicle, and greatly reduces trips to the alignment console.