Move the aligner for use in any bay, on the floor or a lift, with adjustable camera beam.

Supersize your alignment capabilities

Durable, non-electric 3D XL targets

Long-range, high-definition cameras

Alignment reading from three axles at once

Wheel alignments on any surface, in any bay

Capture measurements in a single rolling compensation

Alignment rack integration streamlines processes

See your performance with HunterNet® 2 connectivity

Align a wide range of commercial vehicles

HawkEye XL®

/

Big or small, align them all with HawkEye® XL

Hunter Engineering’s new Hawkeye® XL aligner handles everything from Class 8 trucks down to passenger vehicles.

HawkEye® XL helps Prime Inc. maintain its “nonstop” pace

Hunter’s HawkEye® XL helps Prime Inc. keep trucks moving with nonstop commercial alignment efficiency.

HawkEye® XL Aligner Passenger QuickGrip® Adaptor Demonstration

Explore Hunter’s advanced inspection tech helping shops deliver faster, smarter service with real-time results.

HawkEye XL® Alignment System: Beginner's Operation Guide

Step-by-step guide to using Hunter’s HawkEye® XL for fast, accurate commercial vehicle alignment.

Fast and highly-capable HawkEye® XL heavy-duty alignment machine

Supersize your shop’s alignment power with Hunter’s HawkEye® XL—built for speed, precision, and heavy-duty performance.

Designed & Built in the USA

See how Prime Inc. uses HawkEye® XL to align heavy-duty trucks faster, smarter, and with less downtime.

Ready for your entire fleet

or whatever comes through your door

Industry-standard vision technology

built for commercial vehicles

Alignments in any bay

Multi-Axle Readings

See live alignment readings from three axles at one time with guided procedures.

XL Targets

Hunter's patented 3D targets offer extreme durability, low maintenance, and no electronics at the wheel.

High-definition cameras

Extra-long range, high-resolution cameras precisely monitor each wheel in a 3D space to provide pinpoint-accurate measurements.

Trailer alignment

Long-range cameras easily see targets on 53-foot trailers. Align using optional kingpin adaptor.

Truck Pusher

Optional

Effortlessly move vehicle for rolling comp with rechargeable battery-powered pusher.

Calculate your payback and XL profits

EV Readiness

Prepare for the future

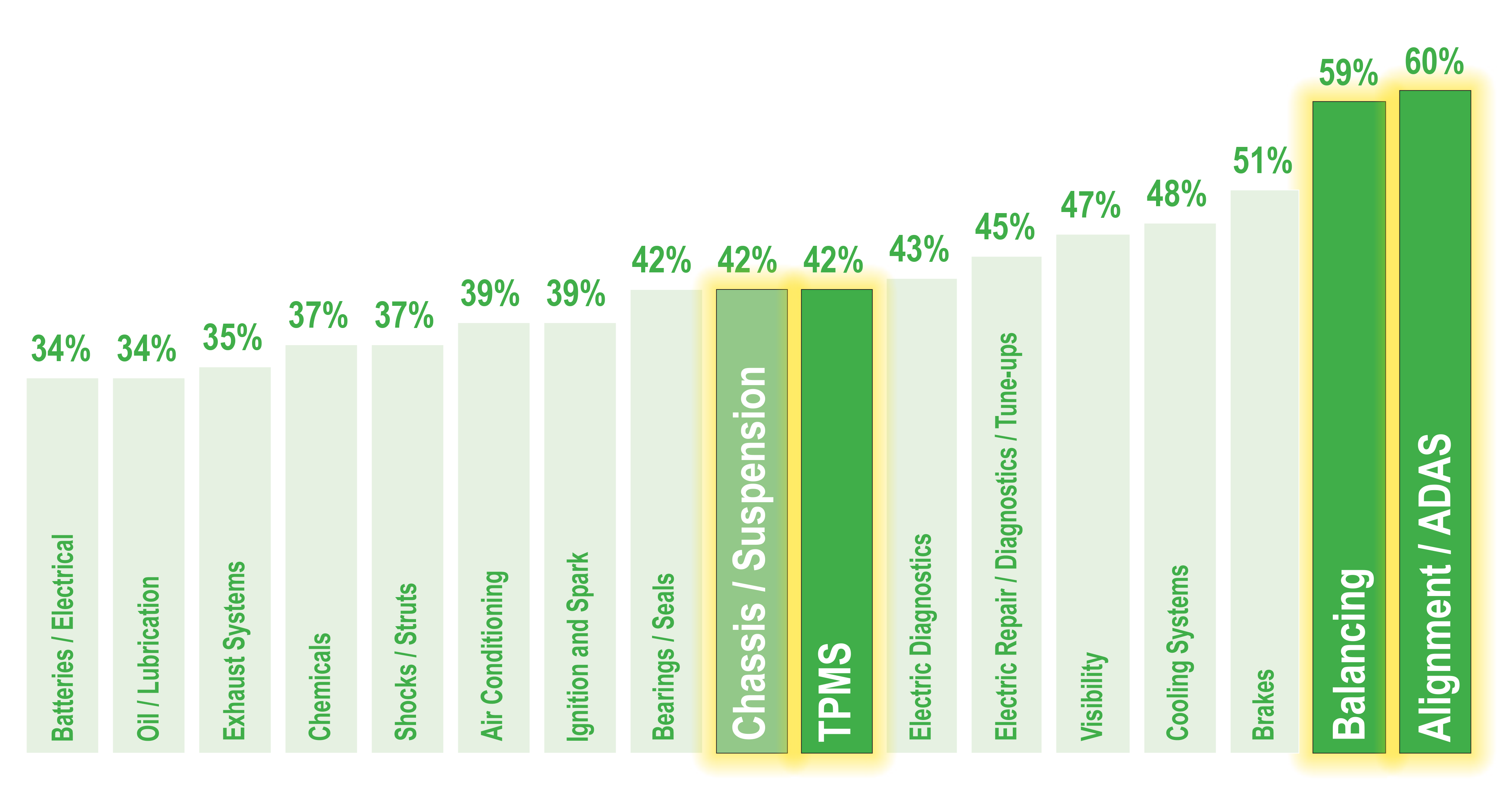

Undercar is the future of automotive service

- Tires are a core service

- High profit margin

- Can supplement other dwindling services

Based on Modern Tire Dealer's 2019 Automotive Service Study

Tech Retention & Recruitment

Simplify the process

Technician-friendly equipment that is easy to use and maintain

- Easier on the body with rolling compensation (no more jacking axles)

- Always ready to use, with no need to recharge or swap batteries

- No electronics at the wheel, putting valuable equipment in harm's way

Customer Experience

XL tire and fuel savings

See what HD alignment can do for your fleet

Approximately 70% of trucks are out of alignment. Proper alignment can save fuel and prevent premature tire wear. Alignment can also reduce driver fatigue, which in turn improves road safety.

Information derived from www.truckinginfo.com

Designed and built in the USA

From raw steel to finished product. When you choose Hunter, you're investing in more than 1,000 American workers.

Want to learn more

about the HawkEye XL®?

Scan the QR code to visit our website for more information

Receive same- or next-day service

Get a free quote or on-site demo

Register for ASE-accredited training

General information & questions

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

We stand beside our equipment and your purchase. Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

Scan the QR code for more information