Hunter's Canada headquarters located in Aurora, ON provides quality service and support to the Canadian market.

A smooth ride starts with precision, and Lee Hunter's work on wheel balancing set the industry standard. His innovative methods improved vehicle stability, safety, and performance for drivers worldwide.

This article was originally published in "Wheel Alignment Equals Motion Balance" by Lee Hunter, Section 2.

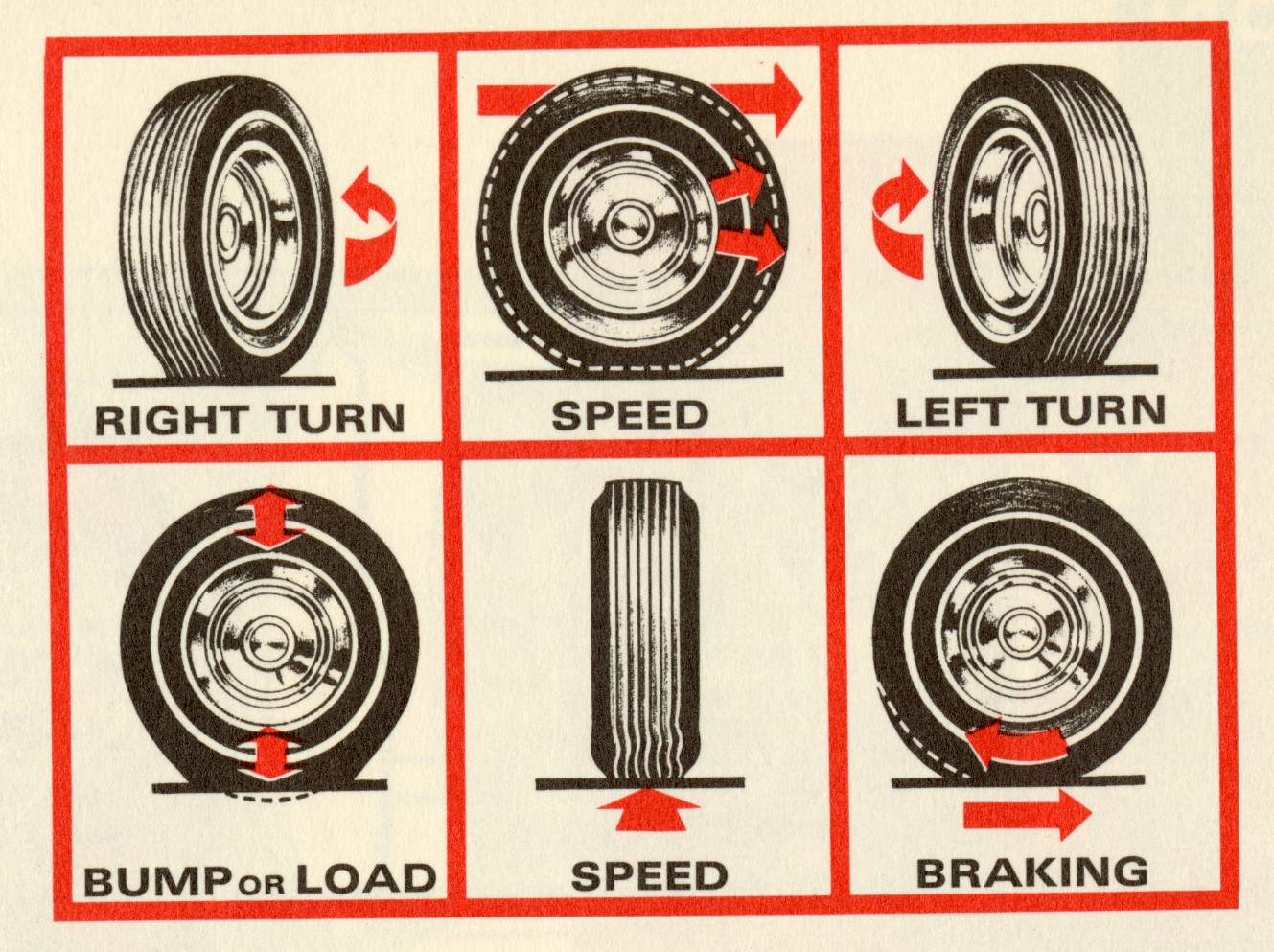

Consider the undesirable action of centrifugal force created by an unbalanced wheel. A wheel that is out-of-balance may not sometimes be critical at slow speeds but may bounce violently at high speeds. Even at slow speeds an out-of-balance wheel will exaggerate the effect of each little bump on the road by causing the wheel to bounce excessively. It is obvious that a bouncing wheel will not hold to the road and should be properly balanced. Also at slow speeds, even though vibration is not particularly objectionable, irregular tire wear continues to shorten tire life.

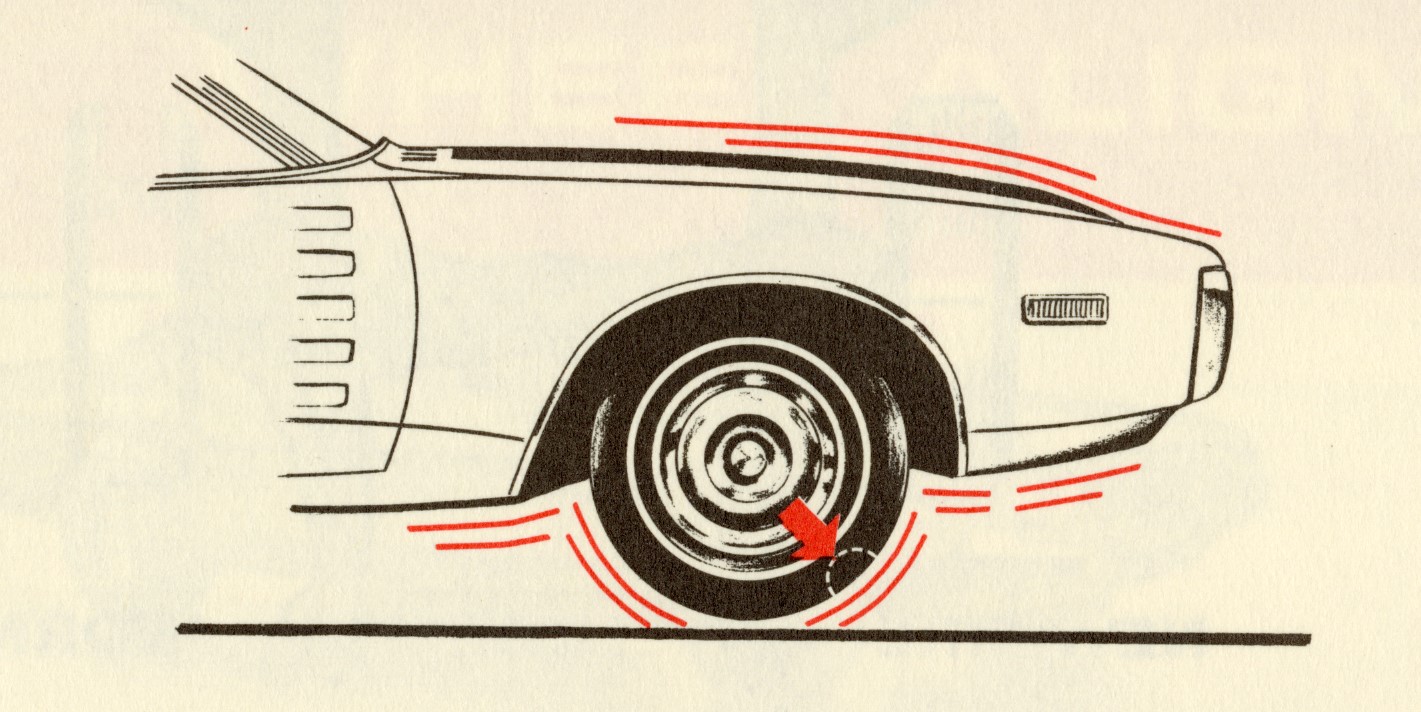

Before attempting to balance the wheel assembly, it is important to make sure that both wheel and tire run true, laterally, and are round (minimal radial run-out). Look for flat spots and tires which are out-of-round. Maximum allowable lateral run-out should be about 3/32 inch. Maximum radial run-out should be about 1/16 inch. It is a waste of time and effort to attempt to obtain correct steering with poor tires on the vehicle.

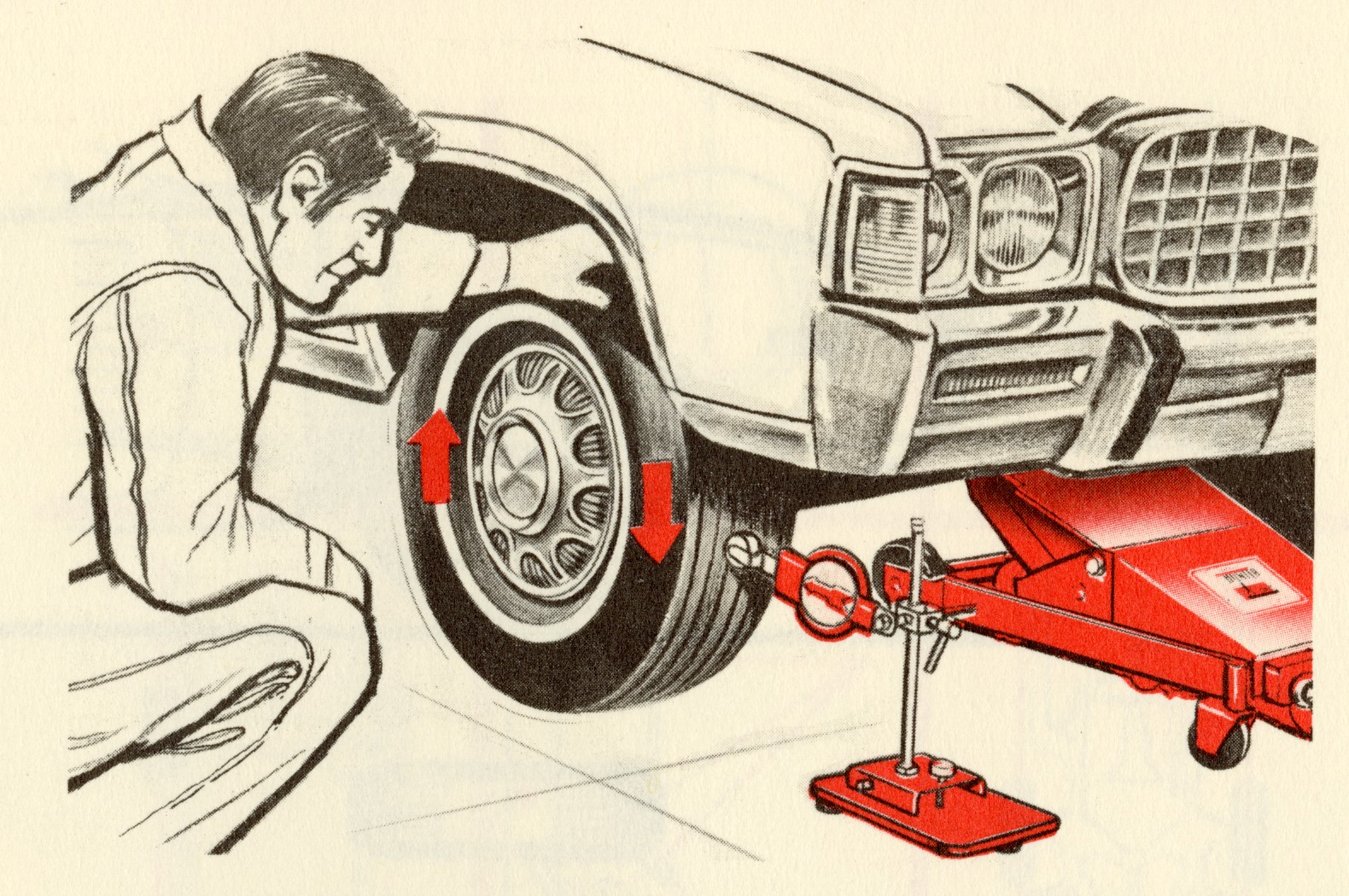

In many cases the lateral run-out of a wheel is due to improper mounting of the wheel on the brake drum assembly. After installing the wheel on the studs and installing the lug nuts, all the lug nuts should first be snugged up very lightly and then gradually tightened a little at a time. The tightening process should be done in about three steps, each step consisting of partially tightening nuts according to the sequence shown in the above diagram, until all the nuts are properly tightened. By following this procedure, you will avoid deforming the wheel to cause both lateral and radial run-out.

Even though a tire is an amazing piece of equipment that, to date, has nothing to compete with it, due to its need for flexibility, it cannot be considered as a unit that is fixed and does not change with even varying situation of the vehicle. Low pressure tires are so flexible that the wheel moves independently within the tire. As the tire depresses between the wheel and the road, the wheel may move up and down, forward, backward, move sideways and twist within the tire itself. These actions may take place at any one or any number of all wheels. With all these variables to contend with, we cannot work with tires that are out-of-round, have too much lateral run-out, and unbalanced wheel and tire assemblies.

The entire tube, tire, wheel, rim, and brake drum assembly should be balanced as a unit and should be checked for balance anytime the tire or wheel is removed from the vehicle. Always re-install wheel and tire assembly to drum exactly as it was before removal. Mark a stud and the corresponding wheel position to use as index marks.

Almost four decades ago, Hunter pioneered simplified wheel balancing which not only eliminated most of the labor involved in a balancing job but helped to remove the mystery from wheel balancing.

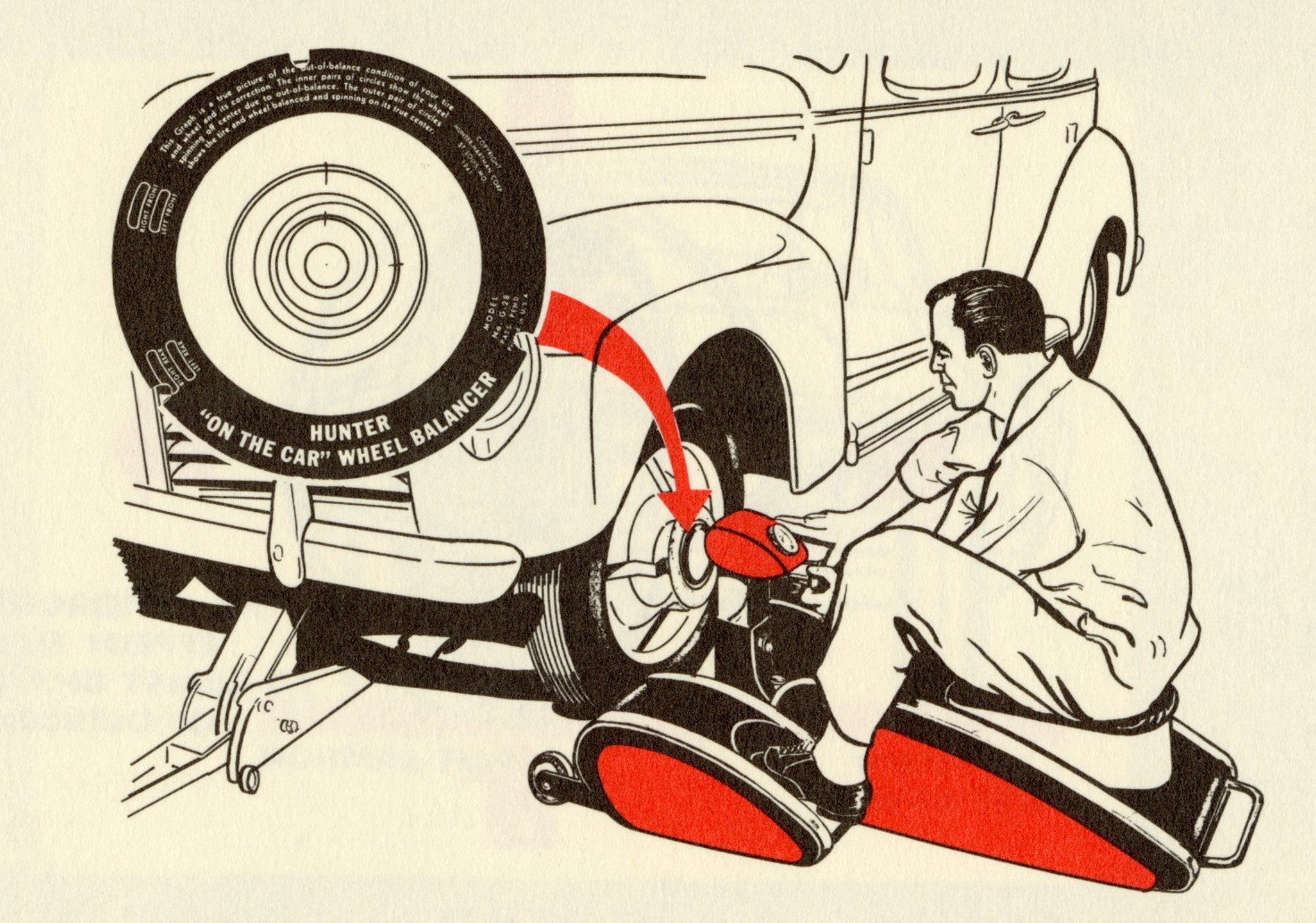

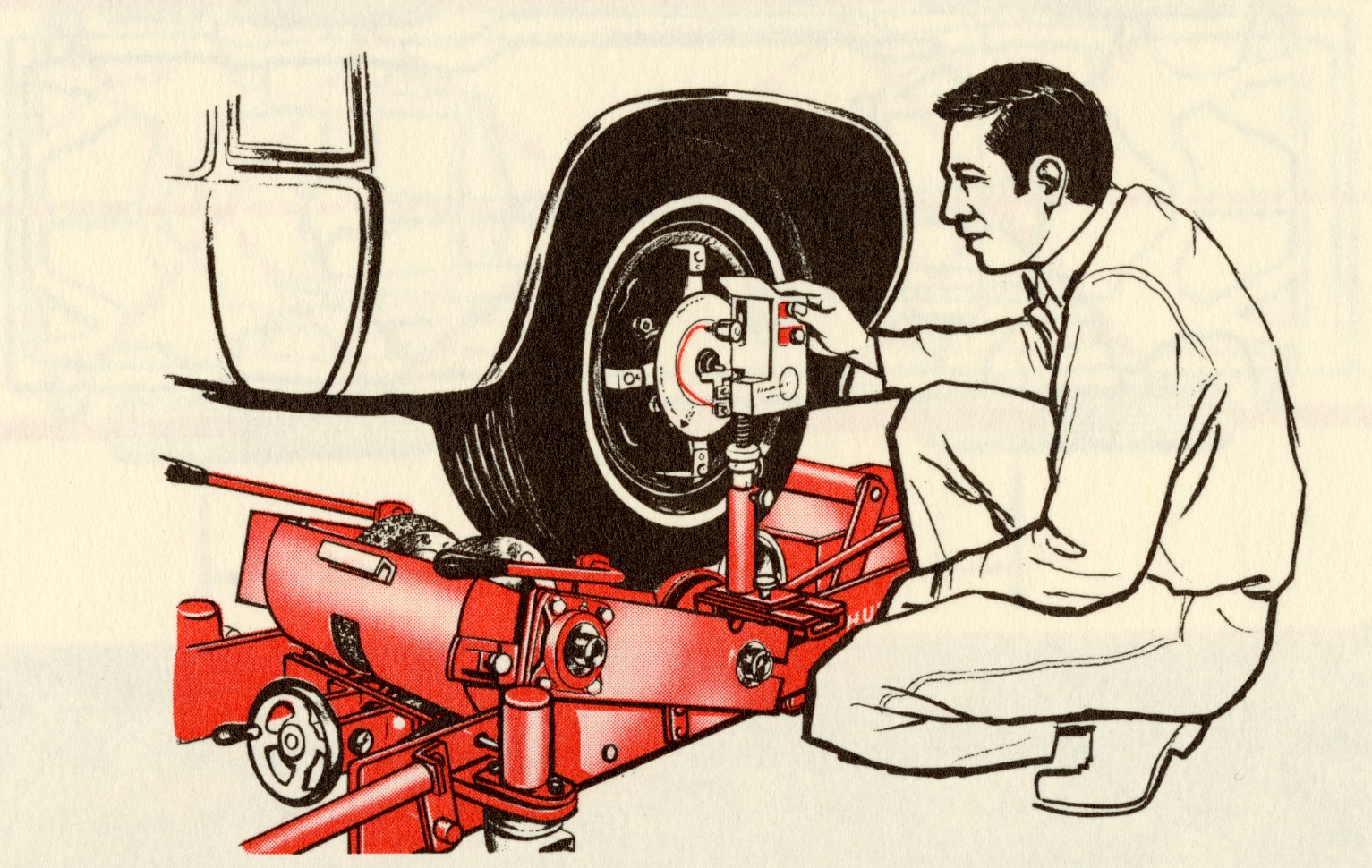

Both the Hunter Tune-In Balancer and the Hunter Electronic Wheel Balance-Indicator balance for kinetic and dynamic out-of-balance conditions in one simple operation, on-the-car, where the wheel can best be balanced. Thereby, eliminating all out-of-balance vibration from the wheel assembly to affect a "motion balance" while the vehicle is in operation. (Illustration shows the Tune-In Balancer in use.)

Hunter also offers the Rapid Dynamic Wheel Balancer, which is the one off-the-car type balancer accurate enough to be included in a class with the two Hunter on-the-car type balancers.

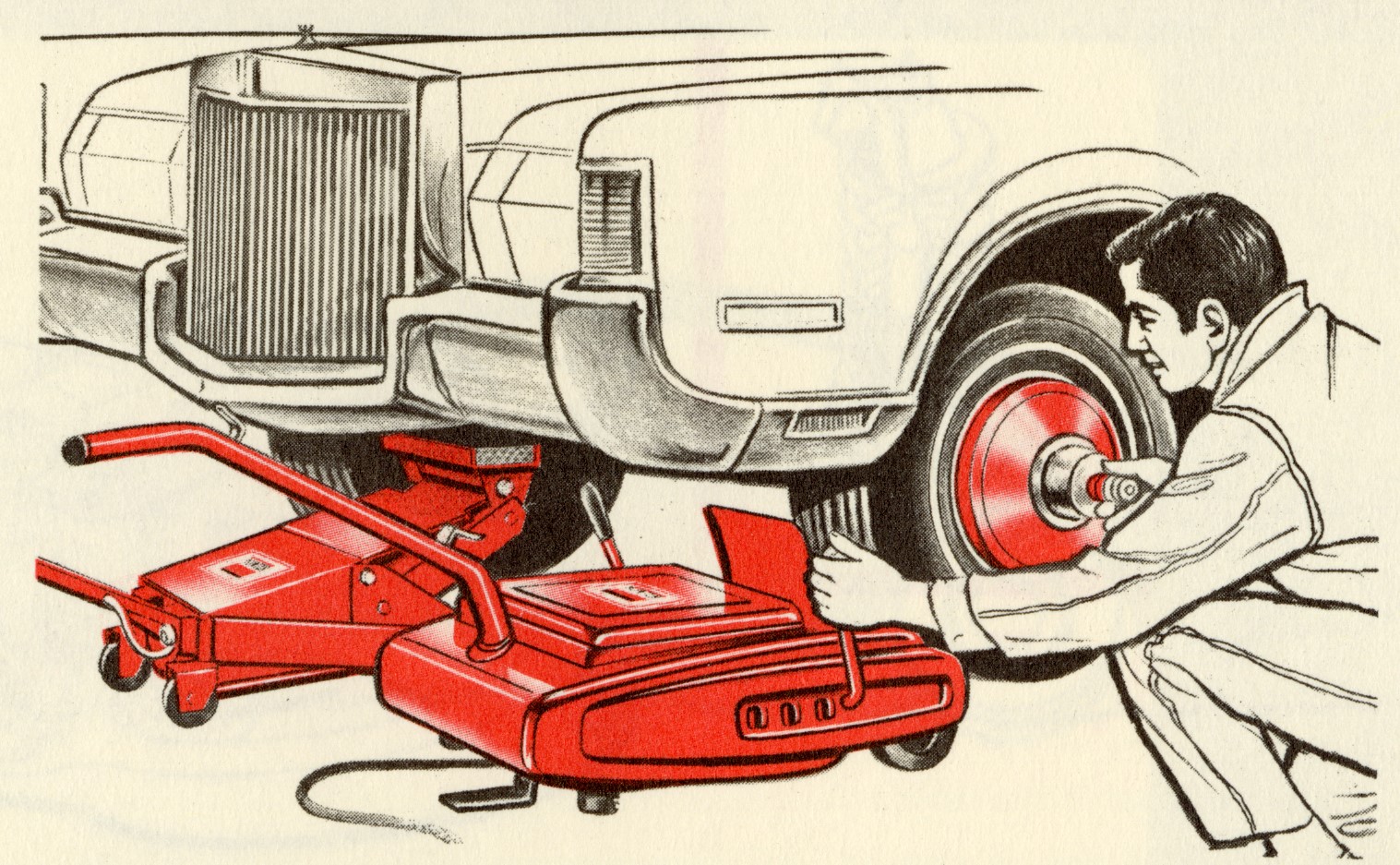

It has become obvious that rear wheel balancing is just as important and necessary as front wheel balancing. It is also best to balance the whole wheel and tire assembly on the vehicle. If a wheel is removed from the hub and drum assembly it should again be checked for balance, because it is being remounted on a different center. (Illustration shows the Hunter "Strobe" Wheel Balance-Indicator in use.)

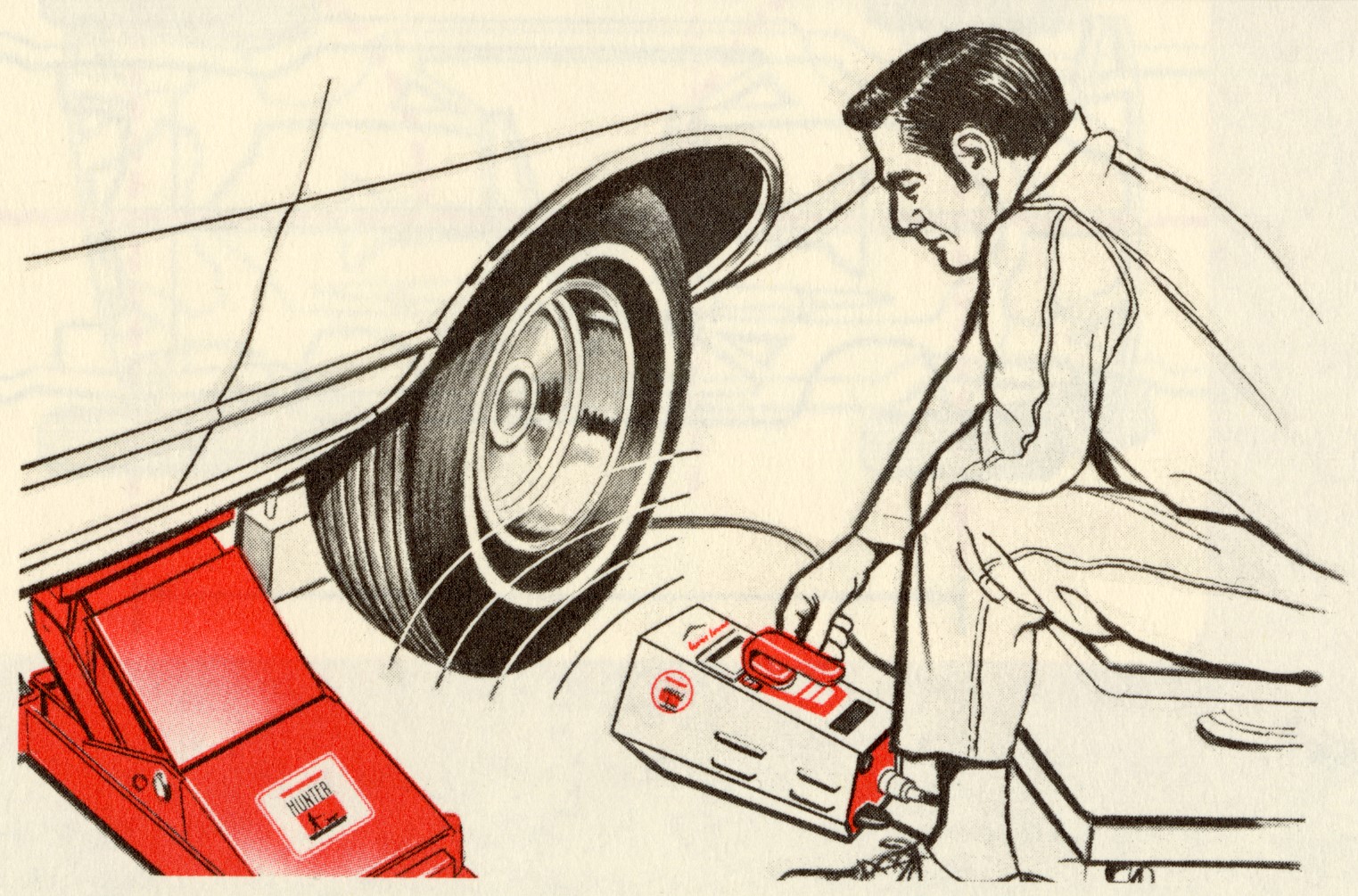

Wheel vibration caused by non-uniformity of tires can be quickly diagnosed and corrected with the Hunter Ride-Perfection Center. Multi-purpose, on-the-vehicle unit dynamically checks tires rotating under normal vehicle load to stimulate actual driving conditions. When pre-set, it automatically and selectively trims inner and outer tire ribs to correct improper tire-uniformity, and accurate, job-finishing wheel-balancing can be performed with built-in 4 H.P. spinner. It is the most-advanced method yet developed to solve vibration problems caused by tire inconsistencies.

We haven't stopped innovating. Check out our present-day wheel balancers.

To give you the best experience, this website uses cookies. By continuing to use this website, you are giving consent to cookies being used.

For information on cookies and how we use them, please visit our privacy statement and our terms of use.