Financing is a great way to lower your upfront cost, and get immediate return on investment. Hunter Financing™ is available in the U.S. and facilitated by GreatAmerica Financial Services.

- Simpler and faster process than a traditional loan

- 25+ years financing the automotive industry

- Knowledgeable about your specific needs

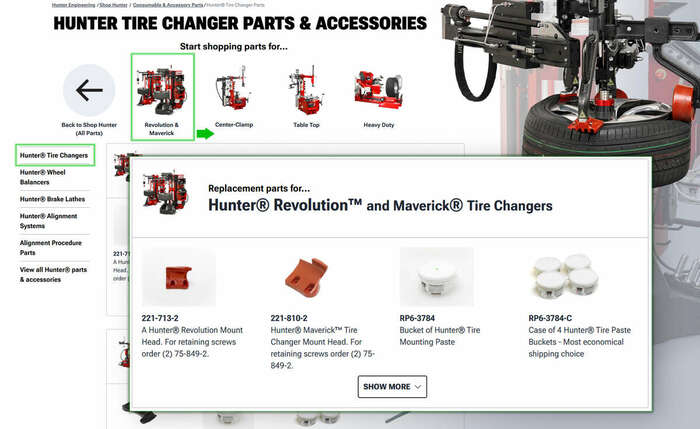

Receive Same-Day or Next-Day Shipping

Receive Same-Day or Next-Day Shipping