- Fast installation

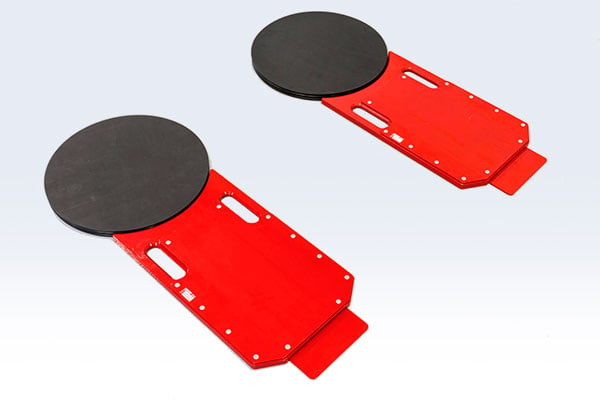

- No metal-to-metal contact

- 2.5 minute inspection using Quick Check® Heavy Duty spec

- No additional software or hardware required

Patented, Optional

Award-winning, patented WinAlign® HD alignment software

Get 3-axle alignment readings in just 3 minutes

Rolling compensation with no jacking required

Quickly diagnose tire wear conditions

QuickGrip® wheel adaptors provide fast, protective installation

Effortless rolling compensations with powered truck pusher

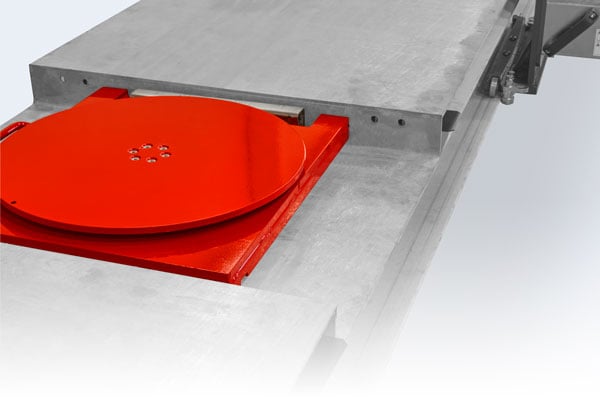

Versatile turnplate and workspace options available

Sally Thomas, Co-Owner of J.P. Thomas & Co., Inc., relies on Hunter heavy-duty equipment at all of their Thomas Tire locations to meet any service challenge that comes their way. Building and maintaining customer trust as well as technician retention are key benefits.

Learn moreSteve Forde, Regional Operations Manager of Bergey's Truck Centers in Philadelphia, PA values the reputation they have with their commercial customers on providing the best service possible with Hunter heavy-duty equipment and the time-savings from their new Quick Check® Commercial system.

Learn moreHunter Heavy Duty customers can now diagnose tire wear conditions in 1/3 of the time. New technology from Hunter Engineering provides accurate, 3-axle wheel alignment readings in just 4 minutes.

HD QuickGrip® Adaptors allow for fast installation and no metal-to metal contact.

Hunter can capture heavy-duty wheel alignment readings in three minutes.

Easy-to-understand printouts help sell service.

Hunter's DSP760T heavy-duty alignment sensors reduce setup time and provide accurate alignment readings.

See all six sensors live to measure alignment angles and diagnose tire wear conditions.

Shown with QuickGrip® adaptors

Patented, Optional

Patent pending

Standard

Hunter's truck pusher allows technicians to effortlessly move the truck from the rear axle for rolling compensation.

Standard on WT600, Patent pending

Send a message to your local Hunter business consultant to receive a free pricing quote or product demo.

Cordless sensor operation with hot-swapable batteries keeps the work area free of tripping hazards.

Short rolling compensation allows technicians to compensate all sensors at once.

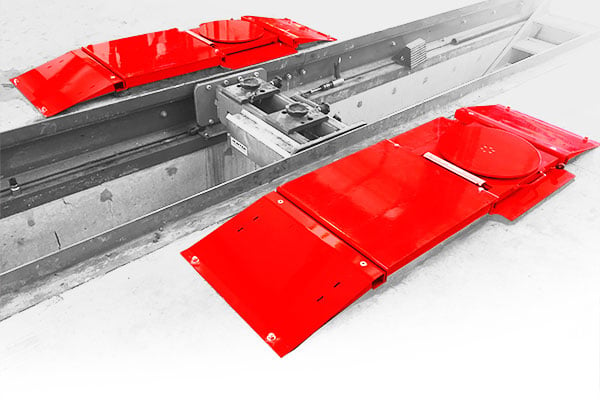

Lock or unlock all PowerSlide® turnplates from the console.

0 axles jacked to compensate

0 sensor movements

81 total walking steps

0 additional minutes required before adjustment

Procedures guide your technicians with step-by-step instructions specific to the vehicle.

Procedures designed so you can complete the work accurately the first time, every time.

Additional features included for servicing light-duty vehicles

See three axles live with all measurements at once. Reduce setup time through minimal sensor movement.

Perform every alignment with a streamlined procedure. ExpressAlign® analyzes each job and presents the optimal action sequence with the minimum steps required.

WinAlign® HD software supports more than 60 customized truck, trailer and bus alignment procedures as well as passenger car and light truck alignment.

Ensure a straight steering wheel every time without repeated adjustments or using a steering wheel holder. Works with all vehicles on the road today, from cars to Freightliners.

Cut adjustment times in half for rear axle corrections. Graphics let you get it right on the first try.

Patented

Calculate the proper bushing size and position adjustment without wasting time with a zero bushing. Eases the process of servicing Ford F-150-450's.

Patented

Measure frame offset angle and calculate adjustments to frame centerline, if a frame reference alignment is needed.

Strengthen technician competency and extend profit opportunities with helpful adjustment videos.

Your local Hunter service representative can answer questions, help with equipment operation and provide on-site training.

Purchase genuine Hunter replacement parts online

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

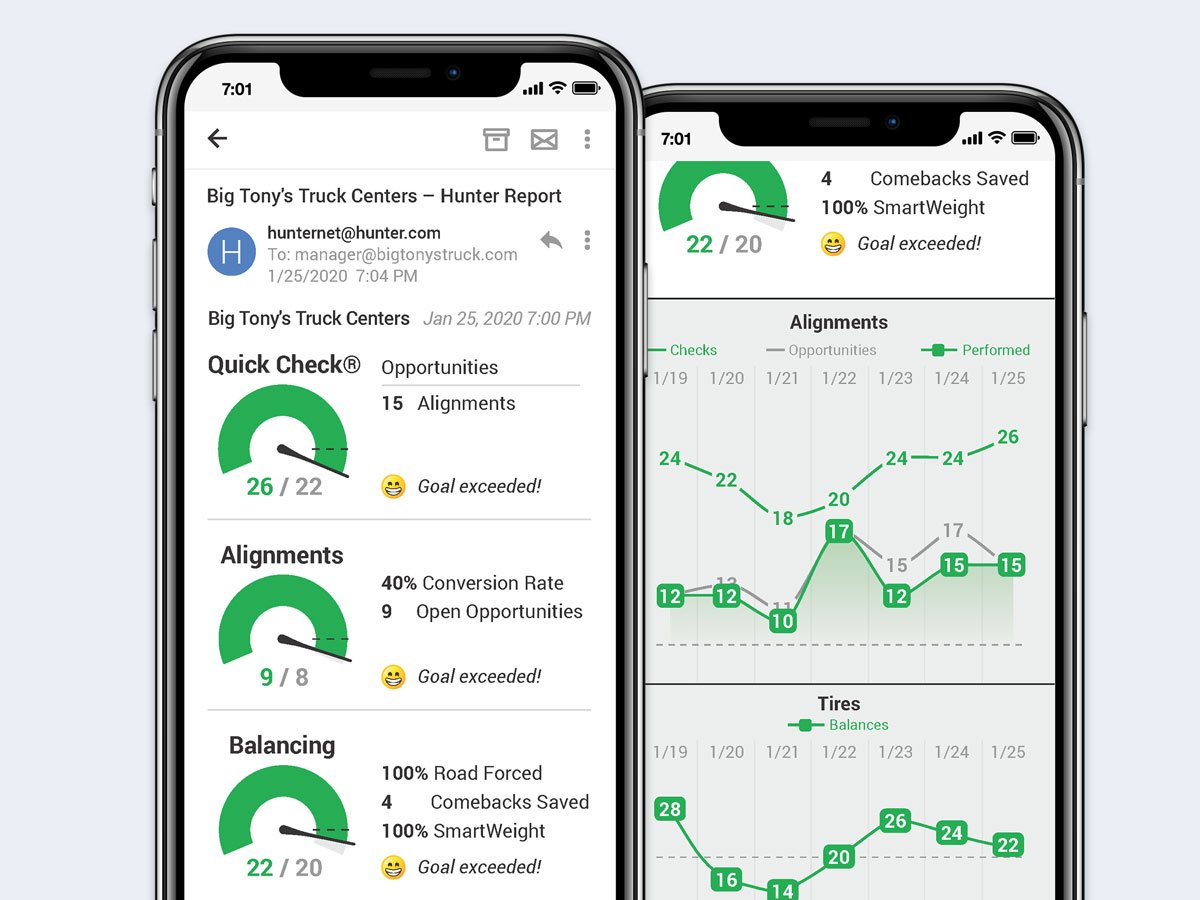

Easy-to-understand report measures output, opportunities & achievements

Easily see shop performance over time and ensure utmost utilization

Automatic, daily delivery via email and text

Financing is a great way to lower your upfront cost, and get immediate return on investment. Hunter Finance™ financing options are facilitated by GreatAmerica Financial Services.

Annual finance amounts in ROIs are estimates and subject to credit approval by GreatAmerica Financial Services.

Financing is a great option to lower your upfront cost, and get immediate return on investment. Hunter Credit™ financing options are facilitated by EasyLease Express™.

Annual finance amounts in ROIs are estimates and subject to credit approval by EasyLease Express™.

Send a message to your local Hunter heavy-duty business consultant to schedule a free on-site demo.

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

Hunter deploys the largest service force of highly-qualified representatives in the industry.

Learn from knowledgable trainers in hands-on equipment usage and classroom learning.

To give you the best experience, this website uses cookies. By continuing to use this website, you are giving consent to cookies being used.

For information on cookies and how we use them, please visit our privacy statement and our terms of use.